The essence of the operation and maintenance SOP is quantifying the standard process from operation and maintenance to taking off the shelf, to maintenance, to on the shelf, and finally to inspection.

Meaning: standardize the standard operation steps and requirements of operation and maintenance (in fact, quantify the details of operation and maintenance);

Purpose: save operation and maintenance time, improve operation and maintenance efficiency, and finally, complete operation and maintenance indicators;

How to do operation and maintenance SOP: You should be familiar with operation and maintenance operations, procedures, and installation and disassembly operation specifications.

1. Dropped miner processing

Principle: Dispose of first and then remove from the shelf;

Processing method: Antsentry guides on-site confirmation and processing;

1) A small amount of disconnection processing

a. Check the network cable (oxidation, damage, etc.);

b. Check the power supply (power fan, wiring, etc.);

c. Check the control board;

d. Check the network cable indicator;

e. Check the running indicator.

2) Batch disconnection

a. Check the shelves are empty, PDU;

b. Check the network structure step by step (with or without loops, loose power, etc.);

c.mac address is repeated.

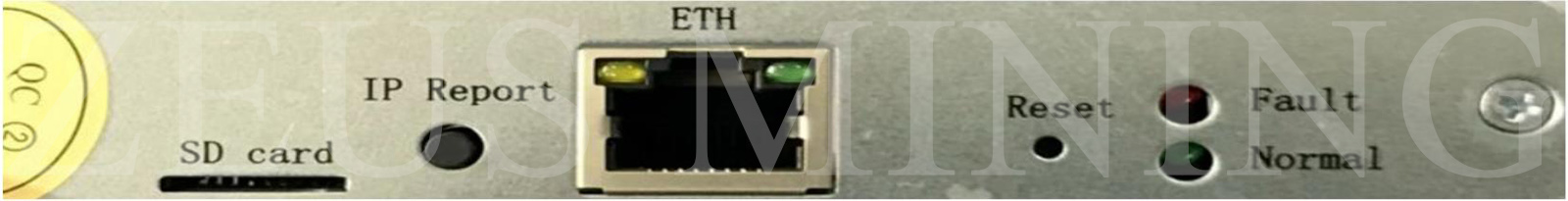

Control board indicator light introduction:

Control board indicator light introduction:

IP Report | Use the IP Report software to feed the miner's IP to the computer. |

ETH | Network Interface. |

Fault | The fault alarm light, in most cases, flashes to indicate that the miner has a fault. |

Normal | Running light, in most cases, the flashing light indicates that the miner is working normally. |

Reset | Miner restores the factory settings button. |

SD card | SD card slot. |

2. Disposal of unqualified miners

a. Whether the cable and power cord are normal; power off and restart, firmware upgrade, reset, etc.;

b. Miners that do not meet the standard high temperature (check the air outlet, miner fan, miner placement, dust accumulation inside the miner, water curtain, etc., large areas of high temperature need to be powered off);

c. If the chip of the miner is dropped, take it off the shelf directly. After the hash board is dropped, check the cable; if the hash board is still dropped, directly taken off from the shelf; if it cannot be started, power off and restart, and the firmware is upgraded;

d. The guide table will confirm removal for maintenance every 8 hours for special models with fluctuations in the hash rate.

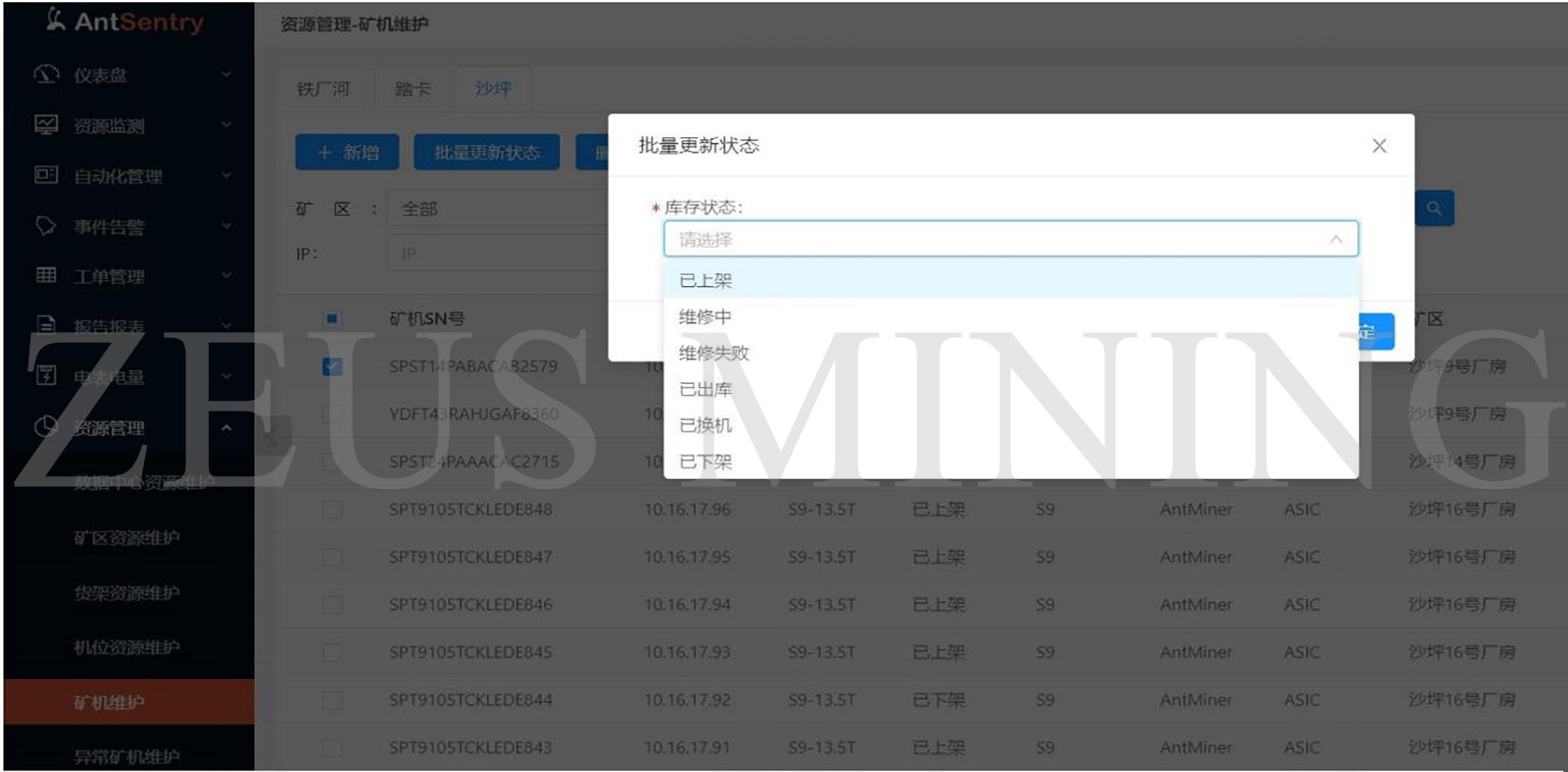

1) The faulty miner is removed from the shelf

Off-shelf management / hosting number maintenance: operate Antsentry system, miner hosting number maintenance - select the companion plant and model to modify the local maintenance number.

After the miners are removed from the rack, the air outlet should be blocked in time to prevent the surrounding miners from experiencing high temperature;

After the miners are removed from the rack, the air outlet should be blocked in time to prevent the surrounding miners from experiencing high temperature;

When there is no unloading and unloading operation, the operation and maintenance engineer will check the accuracy of Antsentry data, the number of online + the number of dropped calls + the number of failures = the total number of custody;

2) Take off the shelf and send it to the miners for repair

2) Take off the shelf and send it to the miners for repair

The operation and maintenance engineer will record the take off the shelf miner. Remove the miner and send it to the maintenance point, or hand it over to the mining farm maintenance personnel for maintenance.

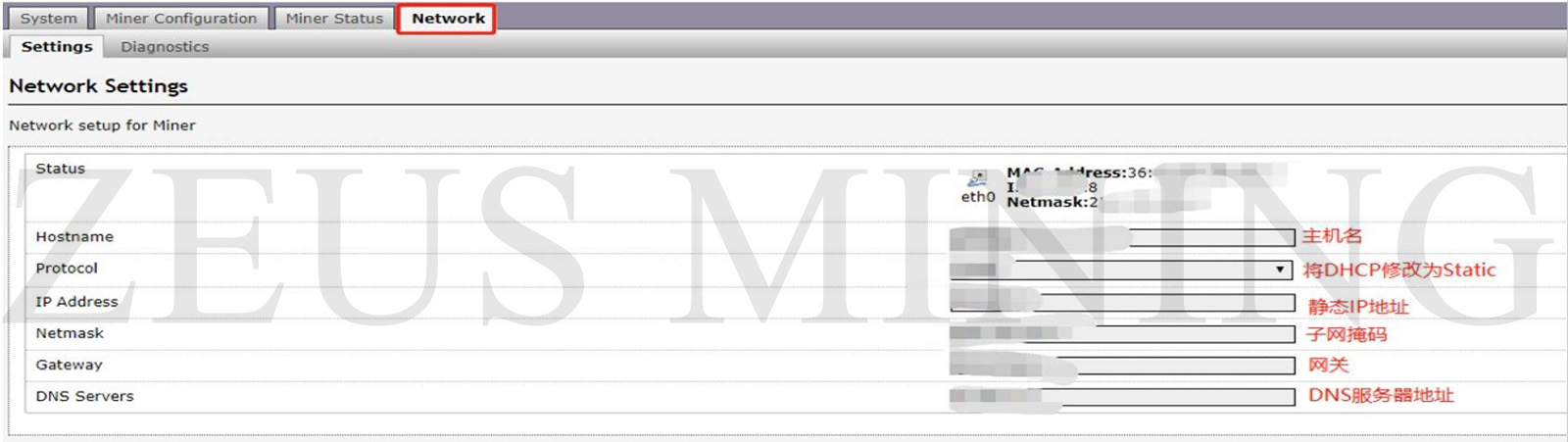

3) Maintenance miner on the shelves operation

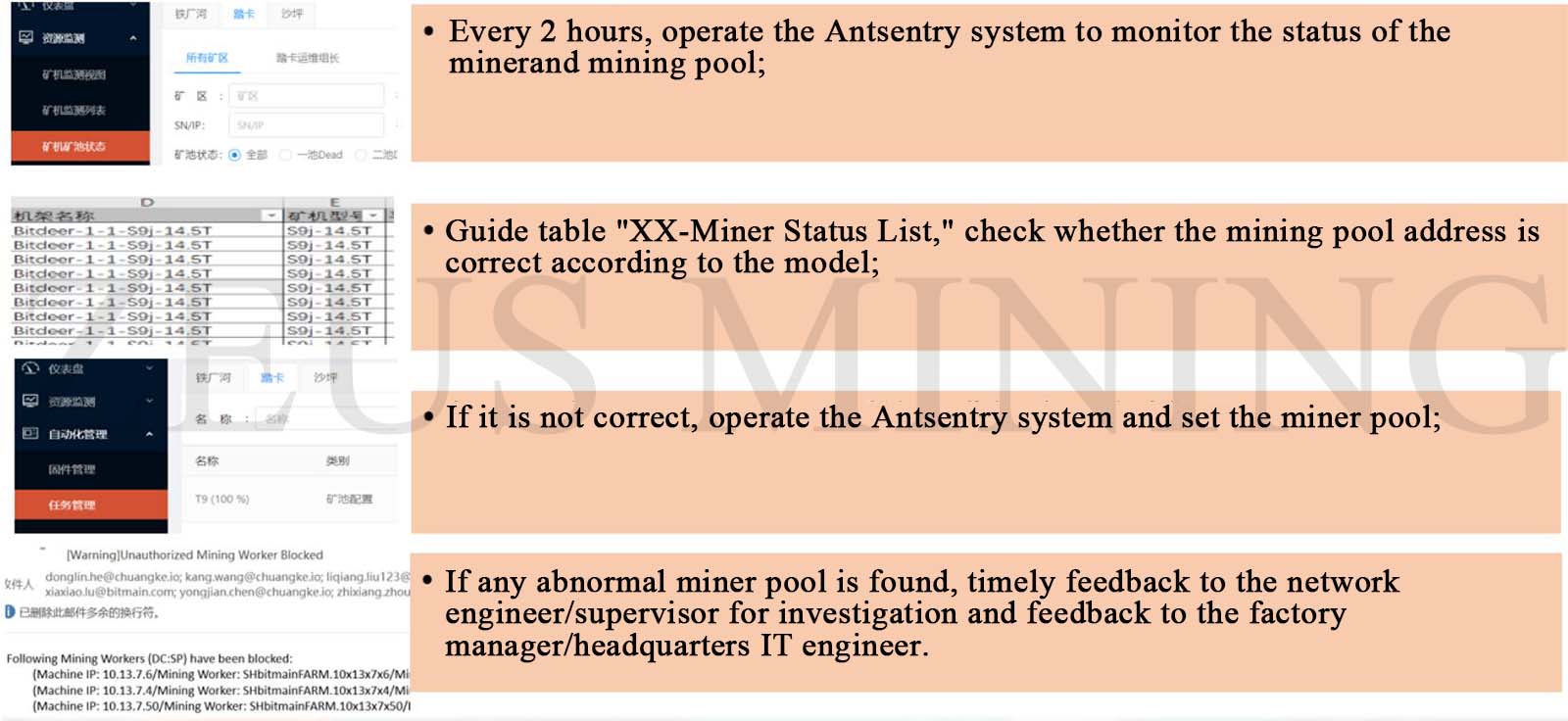

3. Miner mining pool inspection

3. Miner mining pool inspection

4. Comparison of hardware details (who is easier to improve efficiency)

4. Comparison of hardware details (who is easier to improve efficiency)

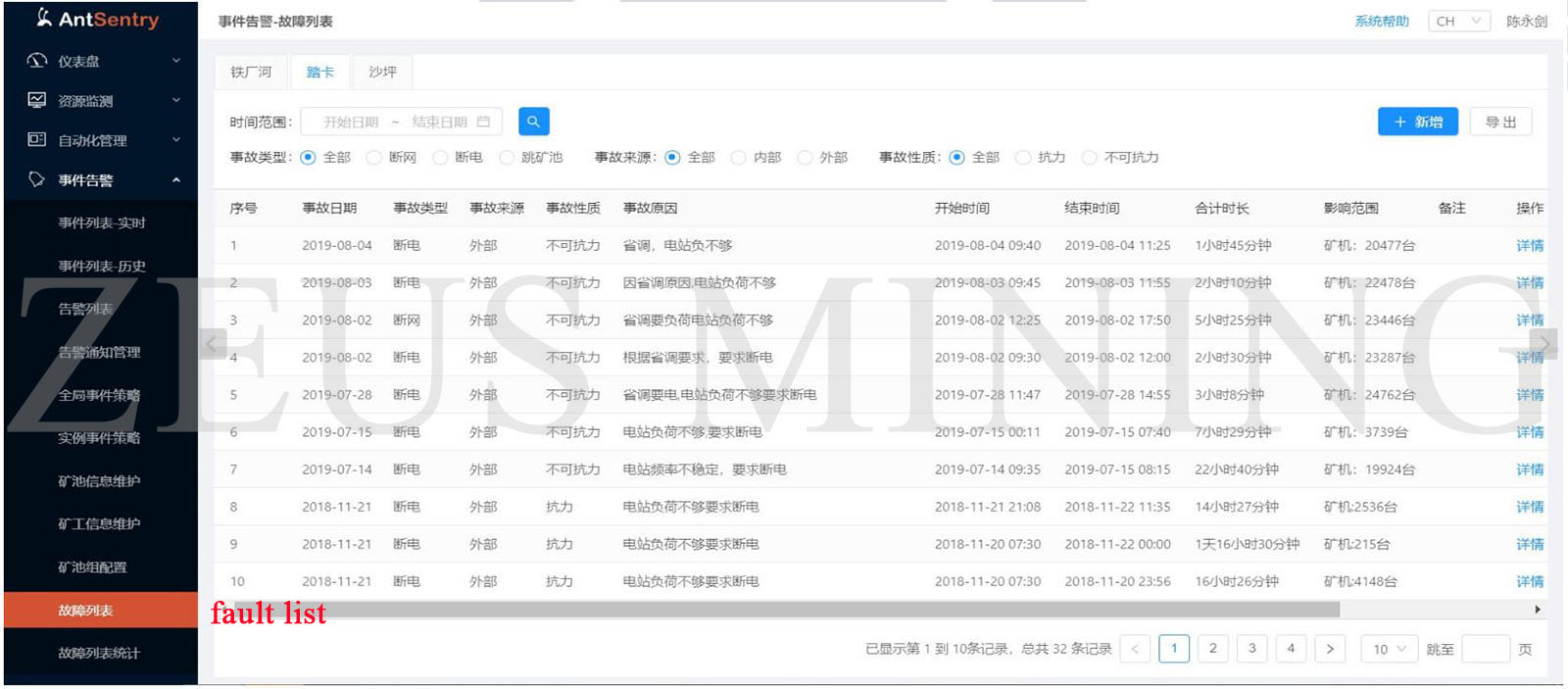

Operate the Antsentry system, event alarm-fault list-new item-enter accident type, accident source, accident nature, start / end time, accident cause, accident type / location.

5. Measured power consumption maintenance

5. Measured power consumption maintenance

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD