Note: It is forbidden to use pure water or tap water in areas with a risk of freezing, and must use matching antifreeze; when repairing or storing, use relevant tools such as an air pump to dry and clean the residual liquid inside the water cooling plate.

1. Case Study

We found that the following problems occurred during customer maintenance

a. The water-cooled board leaks water when it is powered on.

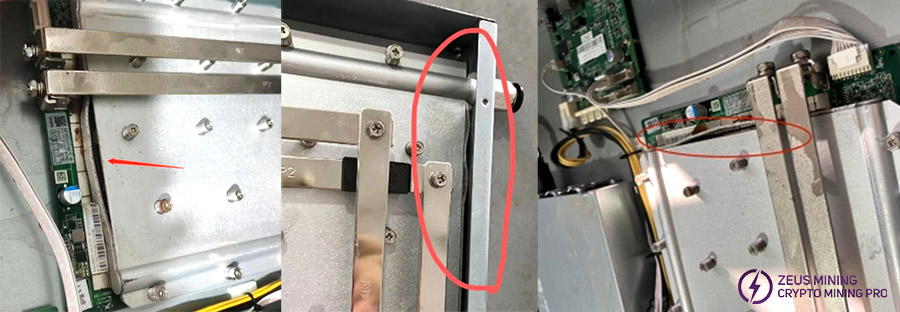

b. The brazing position is bulging and leaking, as shown in the figure below:

c. The connector expands and ruptures, as shown in the figure below:

2. Reason Analysis

After understanding, the customer's indoor temperature is 23°C, and the outdoor temperature is -17°C. The temperature difference is large. After the customer disassembled the machine, the water was not dried, which caused the water in the water cooling board to freeze, expand, explode, or damage the bulge.

3. Matters needing attention

During operation and maintenance, it is strictly forbidden to use purified water or tap water in areas with a high risk of freezing, and corresponding anti-icing fluid must be used;

Antifreeze reference link: Maintenance of AntSpace HK3 V2 container coolant

When reworking, such as transfer, or storage activities, it is necessary to use related tools, such as air pumps, to clean the liquid inside the water cooling board.

Please block the water inlet and outlet with plugs before packaging.

4. Risk

If the liquid is not blown dry during maintenance or moving, it will cause leakage. If the liquid accidentally flows onto the hash board, it may cause it to be burnt and scrapped when powered on. If liquid gets onto the box, it can also damage the box.

If it is a low-temperature area, the expansion of water freezing will cause damage to the water cooling plate and connectors.

Dear Customers,

Hello, May 1-5, 2025 (GMT+8) is China's May Day, and international logistics will be suspended. Our company will suspend shipments on the afternoon of April 30, 2025, and resume warehouse shipments on May 5 (GMT+8). We are deeply sorry for the inconvenience caused to you. Thank you for your trust and support.

Best wishes,

ZEUS MINING CO., LTD

We use cookles to Improve your online experience. By continuing browsing this website, we assume you agree our use of cookies.