Thermal grease is a compound made from silicone oils mixed with materials that have excellent heat resistance and thermal conductivity. This thermally conductive silicone grease is used to enhance heat transfer from ASIC chips, vacuum tubes, CPUs, and other electronic components to their heat sinks, ensuring stable electrical performance of the devices. Due to its good stability and tolerance to high and low temperatures, thermal grease remains paste-like without solidifying under normal environmental conditions.

Thermal conductivity: This is the most critical performance parameter when choosing thermal grease. It refers to the amount of heat transferred through a material with a thickness of 1m and a temperature difference of 1°C across a surface area of 1m² in a specific timeframe, measured in W/mK (Watts per meter-Kelvin). The higher the thermal conductivity, the better the performance of the grease, though this also means a higher cost.

Thermal resistance: Lower thermal resistance in a thermal grease indicates better heat transfer capabilities.

Solid content: The higher the solid content, the higher the viscosity of the grease, giving it a harder texture.

Oil content: Generally, a lower oil content is preferable in thermal grease. High oil content can lead to separation of oil from the grease over time, which can impede thermal conductivity to some extent.

Between the surface of ASIC chips and radiators, or between the surface of aluminum base plates and heat sinks, there are often tiny gaps or uneven surfaces that can affect the rate of heat transfer. In such scenarios, using thermal grease to fill these imperfections can improve thermal conduction by bridging the gap between the heat source and the heat sink. Effective heat dissipation not only reduces the rate of failure but also enhances work efficiency and extends the lifespan of the equipment, leading to better mining profits.

When maintaining the ASIC miner hash board, can I choose thermal grease with any thermal conductivity? The answer is not recommended. Low-coefficient thermal grease may affect the heat dissipation performance of the miner.

At Zeus Mining, a wide range of thermal greases with different thermal conductivities is available, from 0.671W/mK to 11.2W/mK, with options for custom solutions. So, how do you choose the most suitable thermal grease for your mining rig?

· For general computer and electronic devices, thermal grease with a thermal conductivity of less than 3W/mK is usually sufficient.

· For use on ASIC miners, need to choose silicone grease with a higher thermal conductivity. The higher the thermal conductivity, the better the performance, meaning more effective heat transfer from the ASIC chips to the heat sink or water cooling plate.

· If your mining environment and operating temperatures are on the lower side, it's recommended to select thermal grease with a thermal conductivity of 5W/mK or higher. For higher temperatures, opting for thermal grease with 8W/mK or above is advisable. If cost is not a consideration, using thermal grease with more than 10W/mK thermal conductivity will yield the best heat dissipation results.

Selecting the right thermal grease is critical for maintaining the efficiency and longevity of your ASIC miner. By choosing a grease with appropriate thermal conductivity for your specific needs and environmental conditions, you can ensure optimal heat dissipation, which is vital for the reliable operation of your mining equipment.

Zeus Mining offers thermal grease in cans and tubes. For tube-packaged paste, it can be directly applied to the chip or heatsink surface through its tip. For grease in cans, a tool similar to a scraper is needed to extract the grease before applying it to the chip or heatsink surface. It's crucial to avoid overapplying thermal grease, as this can lead to waste, increased thermal resistance, and reduced heat dissipation performance. Additionally, products with higher thermal conductivity tend to have poorer flow properties, making them prone to creating bubbles and uneven coverage, which could compromise the final heat dissipation effect. Therefore, uniform application of the thermal grease is essential.

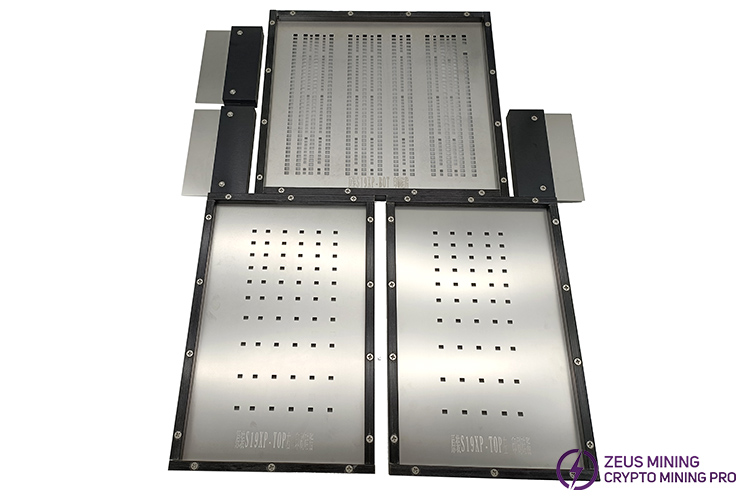

For a quick and uniform application of thermal grease to the chip surface, it is recommended to use a thermal grease stencil designed for hash board model. The stencil can help precisely align the chip positions, allowing for a swift and even application of thermal grease using a spatula, without damaging the surrounding small components.

Under high-temperature conditions over long periods, it's normal for thermal grease to dry out or crack. However, hardened grease can affect the operational efficiency of mining rigs. Therefore, miners are advised to regularly inspect and maintain their equipment. Once the heat dissipation performance is found to be reduced, the thermal grease should be replaced and reprinted to extend the service life and enable the mining machine to achieve optimal mining efficiency.

Adjusting thickness according to conditions: The application thickness of thermal grease needs to be adjusted based on the specific application environment and usage conditions. For example, in high-temperature environments, thermal grease may become softer or thinner, necessitating a thicker application to ensure effective heat transfer. Conversely, in colder environments, thermal grease might harden, requiring a thinner layer to avoid increased thermal resistance.

Consideration of other components: The thickness of the application also needs to take into account the components in the device. Excessive gaps between the thermal grease and the heat sink can prevent full contact with the chip, negatively affecting heat dissipation. In such cases, applying a thicker layer of thermal grease can help fill these gaps and improve heat dissipation efficiency. The correct thickness can enhance heat dissipation performance, extend the lifespan of the device, and ensure stable and efficient operation.

Surface preparation: Before applying thermal grease, it's essential to thoroughly clean the surfaces of the chip and the heat sink to ensure a good seal and the absence of any impurities. Using professional cleaning agents and tools for this purpose can maximize the effectiveness of heat dissipation.

Following these precautions can significantly improve the performance of thermal grease in maintaining the operational efficiency and longevity of mining rigs and other electronic devices. Proper application not only ensures optimal thermal conductivity but also protects against potential issues related to improper use, such as overheating and reduced device performance.