When repairing hash boards, you might need to replace a faulty ASIC chip with a new one. However, new ASIC chips usually don't have any solder on their pins, so they need to be pre-tinned before soldering onto the hash board. To ensure the tinned solder is applied evenly and quickly, you can use a tin tool designed specifically for this purpose. Tin tool, also known as tin planting fixture, is made from electrically heated high-temperature composite materials and can be customized with different hole patterns for various chip sizes. During the process of replacing the chip, it can effectively prevent the generation of charges and protect the chip. It is one of the important tools for repairing the ASIC miner hash board.

Without pre-tinning the chip pins, the chip might not fully contact the pads, leading to poor soldering. Manual tinning may result in uneven application, and excess solder paste could cause solder bridges or short circuits.

How to use tin tools:

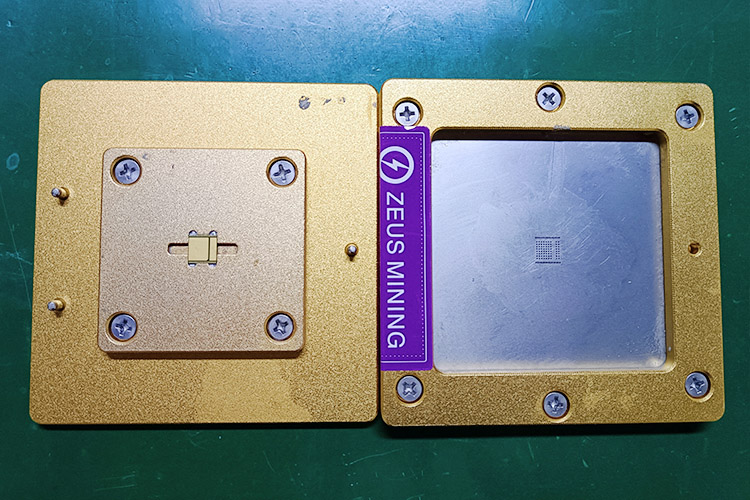

1. The tin tool consists of two parts: a base and a stencil. First place the tools on the workbench and place the base and template respectively.

2. Open the chip's braid, using fine-point tweezers to extract the chip.

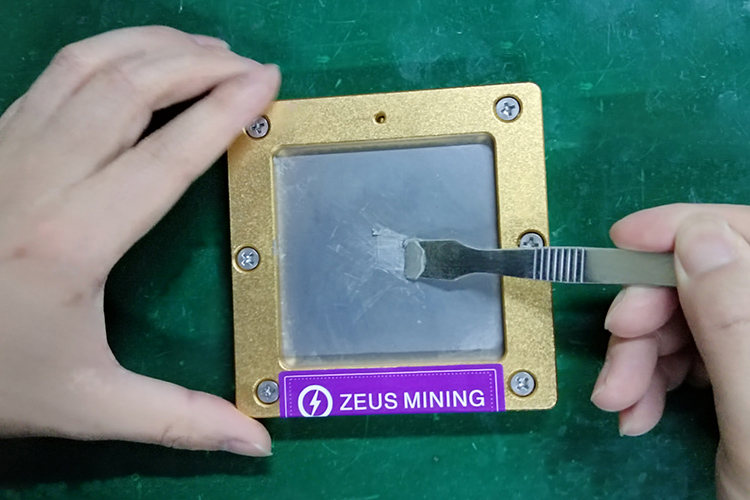

3. Place the chip face down on the base. Align the stencil's holes with the pins of the chip, then place the stencil on top of the base.

4. Add solder paste to the stencil and use a scraper to spread it evenly over the stencil's holes. The pressure from the scraper forces the solder paste through the stencil's holes and onto the chip's pins.

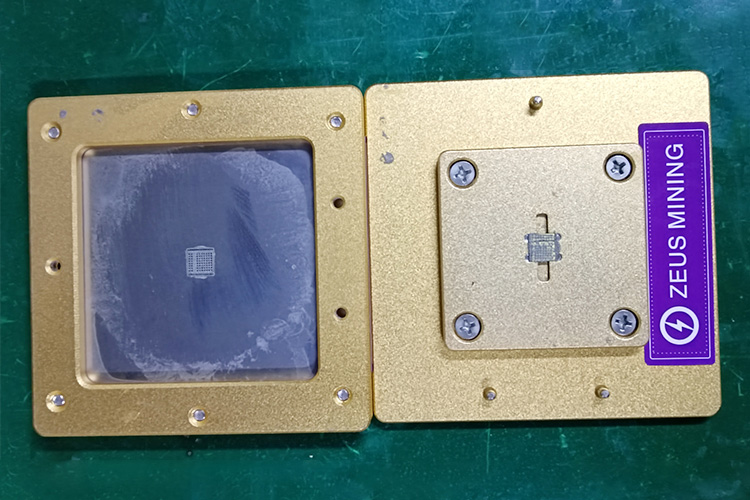

5. Remove the stencil from the base, then use tweezers to remove the chip from the base.

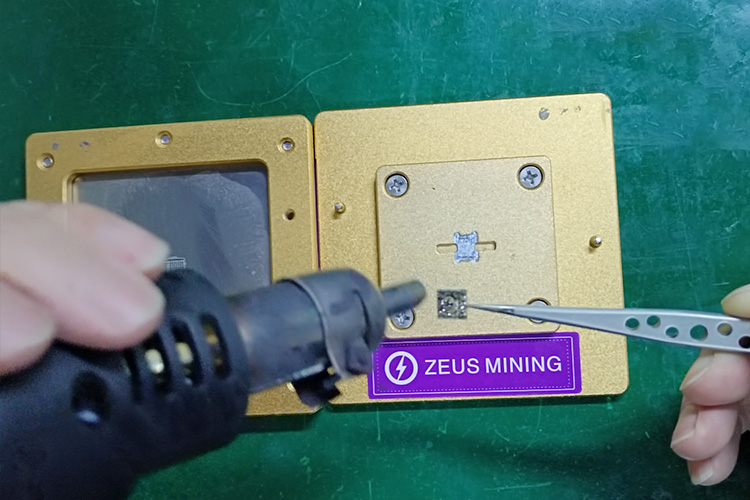

6. Hold the chip by its edges with tweezers and use a hot air gun to heat the chip's pins, melting the solder paste to complete the tinning plating.

Using a tin tool is more efficient than solder balls, saving time and boosting repair efficiency. Once you've pre-tinned the ASIC chip, it’s ready to be soldered onto the hash board to replace the faulty chip, helping restore the hash board's operation, extending the miner’s lifespan, and increasing mining profitability.

Note: Different ASIC chips come in various sizes and pin configurations, so be sure to choose the correct model of tin tool and stencil for your specific ASIC chip.

This method can also be used for tin plating tools for other ASIC chips and control board CPU chips.

Dear Customers,

Hello, May 1-5, 2025 (GMT+8) is China's May Day, and international logistics will be suspended. Our company will suspend shipments on the afternoon of April 30, 2025, and resume warehouse shipments on May 5 (GMT+8). We are deeply sorry for the inconvenience caused to you. Thank you for your trust and support.

Best wishes,

ZEUS MINING CO., LTD

We use cookles to Improve your online experience. By continuing browsing this website, we assume you agree our use of cookies.