ASIC chip A3201FPV3, used to replace the faulty ASIC chip of Canaan Avalon A1166, A1166PRO and A1246 hash boards.

It is inevitable that ASIC chips will age or wear out after running for a long time. When one or more A3201FPV3 ASIC chips on the hash board are damaged or fail, the hash rate will become low or 0. This will cause the miner to be unable to work normally or even shut down, affect normal profitability..

ASIC chips will inevitably age or wear out after running for a long time. Taking the Avalon 1246 miner as an example, the specific replacement steps are as follows:

1. Disassemble the A1246 miner and take out the abnormal hash board: Remove the control board cover, use a screwdriver to unscrew the conductive copper sheet and fan bracket fixing screws, and unplug the hash board cable. Remove the failed hash board and place it on an anti-static mat.

2. Locate the faulty chip: Use the Avalon test fixture to quickly locate the faulty chip. Clean the hash board and remove the heat sink.

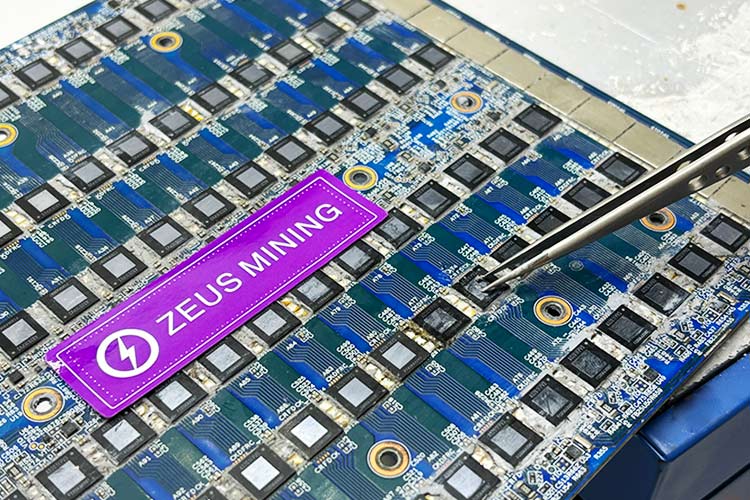

3. Desoldering the faulty chip: Preheat the constant temperature heating platform to about 300°C. After applying no-clean flux around the faulty A3201FPV3 ASIC chip pins, place the faulty ASIC chip area of the hash board on the heating platform (Please wear heat-resistant gloves when using to avoid scald). When we see the tin on the chip pins starting to melt, use tweezers to gently hold the chip, lift and remove the chip. Place the hash board on a repair bench to cool, then use circuit board cleaner and dust cloth to sweep away soldering residue.

4. Tinning the chip: Use the chip tin tool to evenly tin the new A3201FPV3 ASIC chip. For specific instructions, please see "How to use the tin tool?"

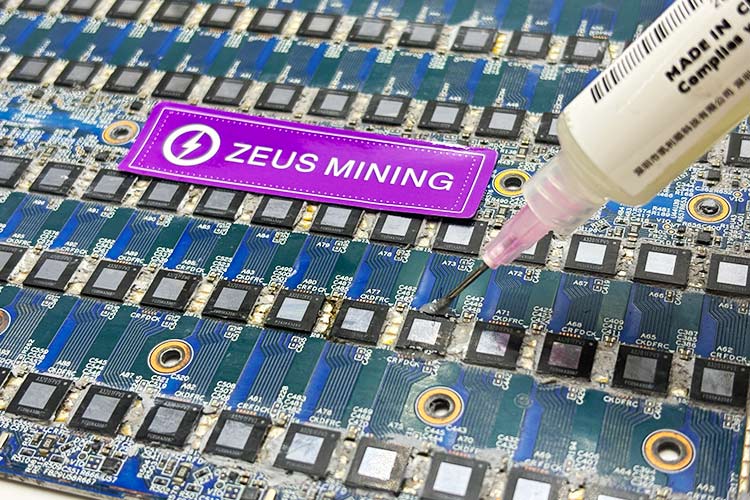

5. New chip welding: Add a small amount of flux to the pad of the chip (If the pad has insufficient tin, we also need to add a small amount of solder paste to tin it.). Use tweezers to pick up the new A3201FPV3 chip and align its pins with the chip pads. Then use a heating platform to heat the pads until the solder paste grabs onto the chip pins. Then use tweezers to gently press the chip for a few seconds to ensure that the chip pins and pads are in tight contact. Remove the hash board from the preheating table and use a fan to cool it. Use circuit board cleaner to clean away any remaining tin and flux.

6. Chip pin test: Use a multimeter to detect the ground value of the chip pin to ensure that the welding is qualified; then use the test fixture to detect the status of the hash board to ensure that the chip replacement is successful.

7. Whole machine test: After evenly applying thermal grease on the chip surface, install the heat sink on the hash board. Then put the hash board back into the miner box and assemble the miner, power on the whole machine and run the test.

Only miners that operate stably can ensure that miners earn huge profits. Timely replacement of the failed A3201FPV3 ASIC chip can not only quickly restore the miner's normal operation but also extend its service life and increase its profits.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD