BOZAN 946C+ constant temperature preheating platform uses an aluminum alloy panel and has an LED digital temp display. It is small in size, precise in temperature control, fast in heating, simple to operate, easy to use and carry. It is widely used in ASIC miner hash board repair.

The constant temp heating platform can be used for Antminer, Whatsminer, and Avalon series aluminum substrate hash board chip desoldering, soldering repair, SMT electronic component repair, etc.

Taking the replacement of a faulty ASIC chip of the Avalon hash board as an example, the method of using the constant temperature preheat station is as follows:

1. Preheating: Set the temp of the constant temperature preheating platform at around 300°C, and wait for the heating station to heat up to the set temp. Note: Be sure to wear heat-resistant gloves when operating to prevent scald.

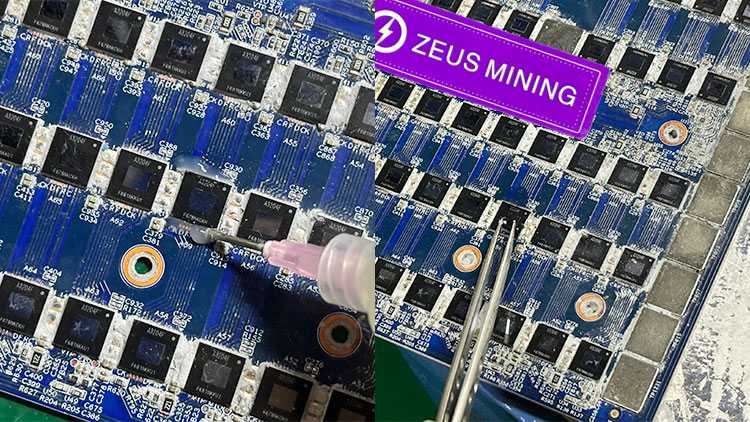

2. Desolder the chip: Use circuit board cleaning fluid to clean around the chip that needs to be replaced, and apply an appropriate amount of flux on the chip pins. When the temp of the heating platform rises to set temperature, the hash board can be placed on the preheat station for heating (only the part of the board where the faulty chip is located needs to be heated, no need to heat the entire board). When we see the tin on the chip pins starting to melt, use tweezers to gently grasp the chip and take it out.

3. Solder the chip: After the hash board has cooled to normal temperature, use circuit board cleaner to clean the hash board; and add a small amount of flux on the chip pad of the hash board (If there is insufficient tin on the pad, add a small amount of solder paste). Place the new chip that has been tinned on the pad, and use tweezers to gently adjust it until the pins correspond to the pad. After the heating platform reaches the preset temperature, place the hash board on the platform and heat it until the solder paste covers the chip pins, and then use tweezers to gently press the chip for a few seconds to avoid virtual soldering.

4. Turn on the cooling fan to cool the hash board. Use a multimeter to measure the grounding value of the signal after replacing the chip.

Things to note:

1. When using the preheat station, we must ensure that the equipment ground wire is well grounded;

2. During the operation of the equipment, the surface of the heating platform and its surroundings are very hot. Don't move or touch it until the power is turned off and cooled down;

3. Do not allow the airflow to blow directly on the preheat station, as it will affect its heating efficiency;

4. To prevent high temperature from damaging the heating element, please do not heat the heating element.

5. Don't use heating plates near flammable and combustible items;

6. The preheating platform is a high-temp electronic product to prevent accidents. The power must be cut off when not in use;

7. To extend the service life of the heating platform, please do not use it for a long time at high temperatures (up to 300°C). Under normal circumstances, the equipment cannot work continuously for more than 8 hours.

The adjustable temperature heating station is a very practical tool for miners. Constant temperature operation can avoid overheating damage to electronic components during the desoldering process and is easy to operate, which greatly improves the efficiency of miners in replacing electronic components and makes the replacement process easier.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD