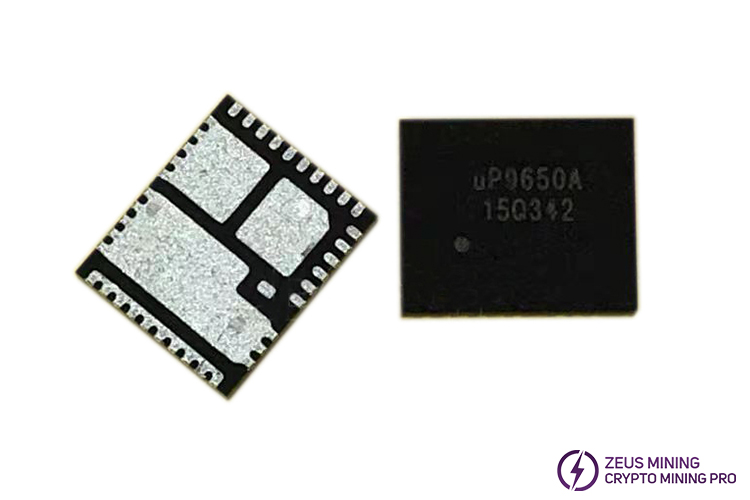

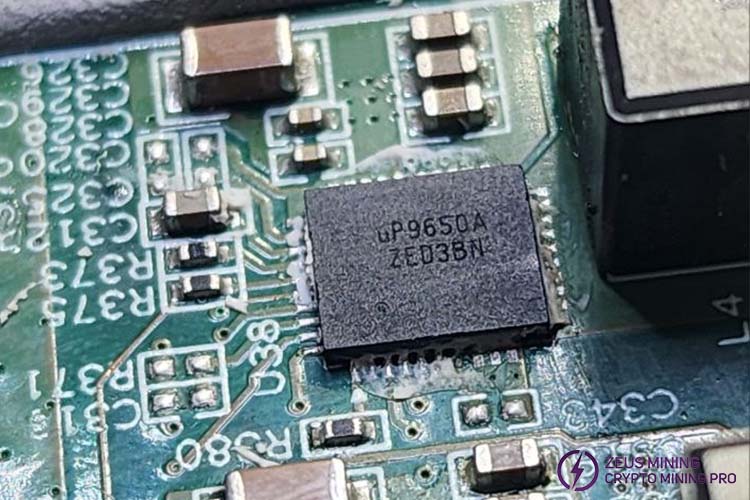

uP9650AQR1 is a powering chip found on the IceRiver KS0 PRO board, specifically located in the power management module on the IceRiver miner's integrated hash board and control board. Its main function is to manage and regulate power input, providing appropriate power to various components of the miner. It is a power management chip specifically designed for digital currency mining equipment, boasting excellent power management performance and protection functions.

When the uP9650A powering chip on the IceRiver miner board is damaged, it may lead to a series of issues such as the miner failing to operate normally, power system collapse or overheating, abnormal heating causing an increase in miner temperature, and performance degradation. This may even pose risks to the safety of the equipment and users. Therefore, when such issues are detected, prompt repair or chip replacement should be carried out to ensure the normal operation and safety of the equipment.

Here are the detailed steps for replacing the IceRiver KS0 PRO uP9650A powering chip:

1. Ensure that the miner has been disconnected from the powering and that there are no power connections.

2. Prepare the necessary tools: including an anti-static insulation pad, flux, a hot air gun, a tin suction wire, solder, circuit board cleaner, dust-free cloth, tweezers, etc.

3. Back up data: If there are important data stored on the miner, it is best to back them up before replacing the chip to prevent any unexpected situations.

4. Remove the integrated hash board and control board: Disassemble the miner's shell, take out the board from the miner, and place it on an anti-static insulation pad.

5. Find the faulty powering chip: Use the miner's technical manual or the layout diagram of the integrated board to find the location of the uP9650A powering chip.

6. Preparations: Ensure that the work area is clean and tidy to prevent dust or debris from entering the board.

7. Desolder the original chip: Apply flux around the pins, set the hot air gun to 2 gears and the temperature to 400℃, gradually heat the damaged uP9650A chip until it can be easily removed with tweezers; and use tin suction wire to clean.

8. Clean the solder pad: Use a dust-free cloth dipped in circuit board cleaner to clean the solder pad at the original chip's position, ensuring it is clean and free of residue.

9. Install the new chip: Apply tin paste, carefully place the new uP9650A powering chip on the solder pad, ensuring proper alignment.

10. Solder: Apply flux and solder, use the hot air gun to solder the new chip to the board, taking care to ensure good soldering quality, with uniform and secure solder joints.

11. Check the soldering: After soldering, use a magnifying glass to inspect the solder joints, ensuring no shorts or poor contact.

12. Overall inspection: Reinstall the integrated hash board and control board back into the miner and connect the power supply. Perform a complete miner test to ensure that the new chip functions normally and the miner operates stably.

13. Data recovery: If there are backed-up data, they can be restored to the miner.

14. Encapsulation and fixation: If necessary, use insulating glue or other encapsulation materials to fix the new chip and ensure good contact with the board.

15. Record: Finally, remember to record the date and detailed steps of the chip replacement for future reference.

Replacing a damaged IceRiver miner's uP9650A powering chip can restore the normal operation of the equipment, improve stability and reliability, reduce the risk of failure, avoid damaging other components, and potentially bring improvements in energy management and efficiency. This will help ensure that the miner can mine continuously and stably, increasing mining revenue.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD