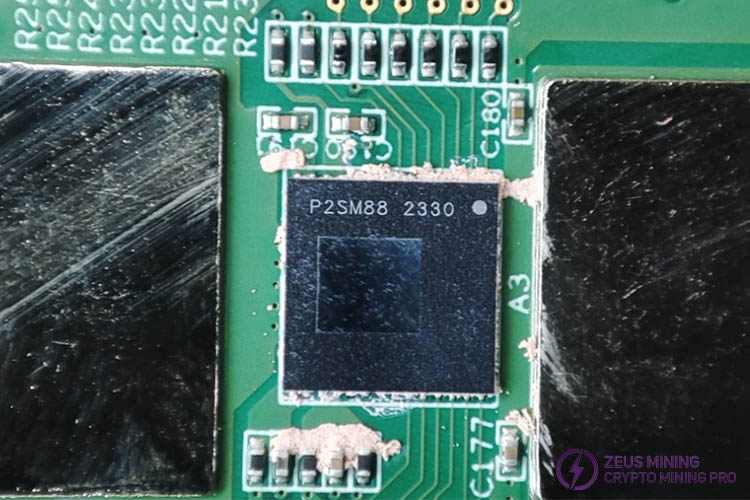

The P2SM88 2330 chip is an ideal replacement part for faulty ASIC chips on the hash boards of Iceriver KS0, KS1, KS2, KS3 miners, with strong compatibility and easy to installation, which can help miners to achieve optimal performance states. It is also suitable for the newly launched Iceriver KS3M KS3L miners.

Iceriver KS0, KS1, KS2, KS3 are widely used due to their excellent hashing rate. However, prolonged operation may lead to issues such as aging and wear of the miner's internal Asic chips, which can affect mining efficiency or even cause downtime. Promptly replacing the faulty chips with new ones can significantly reduce downtime, ensuring stable and continuous high-efficiency operation.

Here are the specific steps for replacing the P2SM88 2330 ASIC chip (taking the Iceriver KS3 miner as an example):

1. Locate the faulty chip

• Remove the protective cover plate on top of the miner, detach the conductive copper sheets and exhaust fans, unplug the cables, and carefully take out the faulty hash board.

• Use the Iceriver KS hash board test fixture to accurately locate the faulty chip. Click here to view how to use the KS fixture.

2. Disassemble the heat sink of the hash board

• Remove the fixing screws of the large heat sink on the front of the hash board and take it off.

• Use a heat gun (around 450℃) to remove the small heat sink on the back of the hash board corresponding to the faulty chip.

• Clean the thermal grease and dust on the surface of the faulty chip with circuit board cleaning solution.

3. Remove the faulty chip

• Apply an appropriate amount of no-rinse flux around the faulty chip pins.

• Set the heat gun to around 400℃ with the wind speed on the second level, then heat the faulty chip. Once the solder is completely melted, carefully remove the faulty chip using tweezers.

4. Cool and clean the hash board

• Use a cooling fan to quickly cool the hash board.

• Then, use lead-free board-washing water to carefully clean the solder residue on the hash board, ensuring a clean surface.

5. Tinning and soldering of the new chip

• Use a tin tool to evenly tin implant the new P2SM88 2330 chip.

• Align the tinned chip pins with the solder pad at the faulty position on the hash board using tweezers and add an appropriate amount of flux.

• Reheat with the heat gun until the solder completely covers the chip pins. Gently press the chip with tweezers for a few seconds to ensure stability.

• Cool and clean the hash board, ensuring no solder residue remains.

6. Chip inspection

• Use a multimeter to inspect the soldering of the chip pins, ensuring no cold solder joints or solder bridges.

• Test the single board using the hash board test fixture to ensure successful chip replacement.

7. Assembly and testing

• Reapply thermal grease evenly on the surface of the replaced chip before reinstalling the heat sink in its original position. (Install the large heat sink on the front of the hash board first, then install the small heat sink on the back)

• Place the hash board back into the miner case, install the conductive copper sheets and cooling fans, then correct connect the cables.

• Power on the miner to check if the performance is normal.

After completing the replacement of the P2SM88 2330 ASIC chip, the miner will continue making contribute to our mining business with excellent hash rates and stability.