GD900 thermal grease is commonly used for the maintenance of whatsminer hash board. Its main raw material is metal oxide with a small particle size, which can fill the gap between the reverse side of the hash board and the heatsink. With a thermal conductivity of 4.8W/MK, it can be applied to the reverse side of the hash board to achieve stable heat dissipation.

Features of GD900:

Efficient performance, reducing the temperature by more than 5°C compared to ordinary thermal grease.

Made of all-oxide metal, with high insulation properties.

Temperature resistance ranges from -50°C to 200°C, and it will not dry out after long-term use.

Syringe packaging for convenient use. The paste is delicate and smooth, easy to apply.

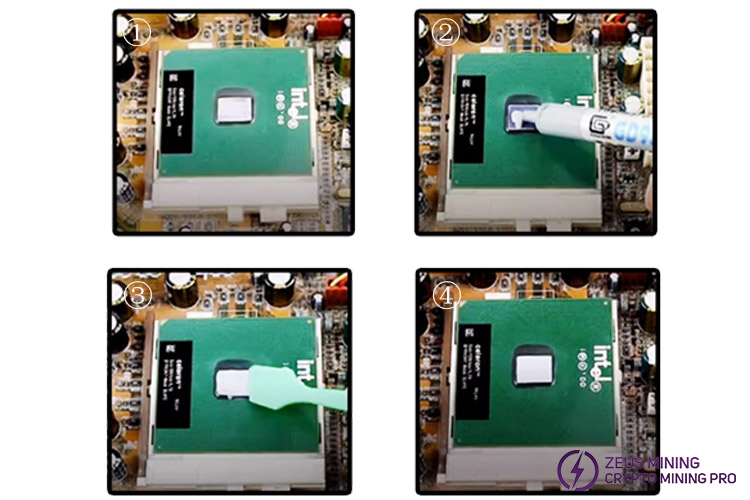

Steps for using GD900:

Prepare the tools: GD900 thermal grease, scraper, dust cloth, and cleaner.

1. Remove the fixing screws of the heat sink and take it off from the front side of the hash board.

2. Unscrew the screws on the hash board and place the reverse side of the hash board upwards.

3. Apply an appropriate amount of GD900 thermal grease to the back of the hash board and spread it evenly with a scraper, covering the entire heat dissipation area. (too much grease may cause overflow, while too little may not ensure that the gap between the chip and the heatsink is fully coated)

4. The application of thermal grease should not be too thin or too thick.

After application, reinstall the hash board onto the heatsink, screw in the screws, and the application of thermal grease is complete.

Note:

During the application process, keep it gentle to avoid generating bubbles or damaging the chip and heat sink surfaces.

After application, carefully inspect and clean up any excess grease to ensure optimal heat dissipation.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD