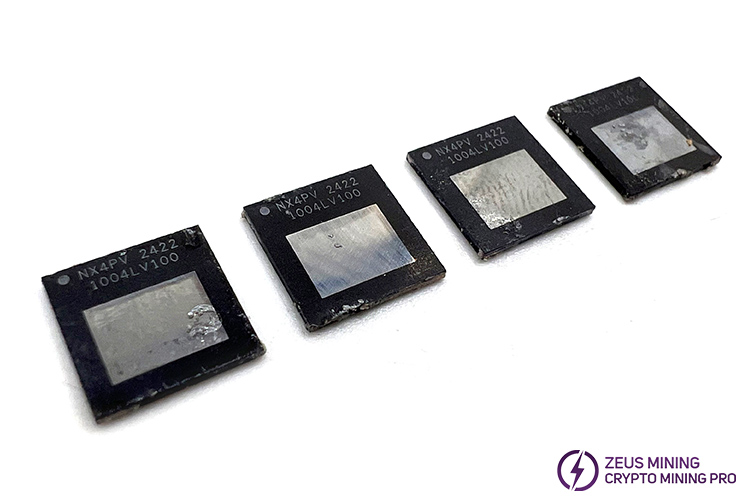

The Iceriver KS5L 1004LV100 ASIC chip is a revolutionary cryptocurrency mining chip with an ultra-high hash rate of up to 12T. It can perform mining calculations at an astonishing speed while only consuming 3400W of power, demonstrating an excellent energy efficiency ratio that ensures efficient mining while maintaining system security.

Prolonged operation of the Iceriver KS5L can lead to issues such as aging and wear of the Asic chip inside the miner. When the chip is damaged, the hash rate will significantly decrease, affecting mining efficiency, potentially causing the device to malfunction or even lose hash rate entirely, resulting in downtime. Promptly replacing faulty chips can significantly reduce downtime and ensure stable, continuous, and efficient operation of the miner.

Here are the steps for replacing a faulty chip:

1. Disassemble the protective shell of the miner, take out the conductive copper sheets and exhaust fans, unplug all connection cables, carefully remove the faulty hash board, and place it on an anti-static insulation pad.

2. Dismantle the heatsink from the hash board and accurately locate the faulty chip using the Iceriver hash board test fixture.

3. Clean the area where the faulty chip is located and apply flux to the chip pins.

4. Use a heat gun (about 400°C) to heat the location of the damaged chip. After the solder on the pins melts, gently grasp the chip with tweezers and remove it.

5. Use a cooling fan to quickly cool the hash board, then clean the residue on the hash board.

6. Use a tin planting tool to evenly tin the new 1004LV100 ASIC chip. Follow the how to use a tin planting tool guide to plant tin on the chip.

7. Use a tweezer to grasp the tinned chip and place it in the pad. Add an appropriate amount of flux.

8. Reheat the area using the hot air gun until the solder completely covers the chip pins. Gently press the chip down with a tweezer for a few seconds to ensure stability.

9. Cool and clean the hash board, ensuring no solder residue remains.

10. Use a multimeter to check the chip's signal grounding value to ensure no cold solder joints or solder bridges.

11. Evenly apply thermal paste to the surface of the replaced chip and reinstall the heat sink.

12. Place the hash board back into the miner box, install the conductive copper sheets and cooling fan, then correctly connect the wiring.

13. Power on the miner and check if the hash board and miner are operating normally.

Replacing new chips help miners solve chip failure problems that may be encountered during mining, reduced downtime and lost profits due to equipment failure. As new miners emerge in the mining industry to meet market demand and compete, optimizations in new algorithms and more efficient chip designs will continue to drive the industry forward. With its powerful performance, reasonable power consumption, and broad adaptability, the Iceriver KS5L 1004LV100 ASIC chip has become an excellent choice in the mining field.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD