If we want to enhance the mining performance of Antminer K7, the K7 water cooling upgrade kit is the best solution. It effectively dissipates the heat generated by the hash board during operation, ensuring the machine maintains a low-temperature operation and effectively avoiding a series of failures that may be caused by high temperatures. At the same time, it also features low noise, providing mining users with a quiet mining experience.

Antminer K7 modify water cooling board effectively avoids the risk of overheating damaging to internal components due to insufficient heat dissipation, and also reduces the noise problem caused by high-speed operation of cooling fans. In addition, it also ensures that the hash board will not be instantly burned out in emergency situations, making it more economical and efficient.

The specific steps for modifying the miner hash board with the K7 water cooling upgrade kit are as follows:

1. After powering off the miner, remove the top protective cover plate, dismantle the conductive copper sheets and cooling fans, unplug the corresponding cables, then take out hash boards to place them on an anti-static insulated workbench.

2. Remove the heat sink on the front of the hash board, after that use a dust-free cleaning cloth and circuit board cleaning solution to clean the board.

3. Prepare 3 bottles of 110g 4.0W/mk hash board thermal grease, use a silicone grease mold to evenly re-apply thermal grease to the chips surface to ensure effective contact with the water cooling plate.

4. Align the water cooling plate with the screw holes on the hash board and then tighten the fixing screws.

5. Modify the other two hash boards in the same way, then place the hash boards back into the miner case.

6. Reinstall the previously removed conductive copper sheets to the output end of the power supply, fix them with screws.

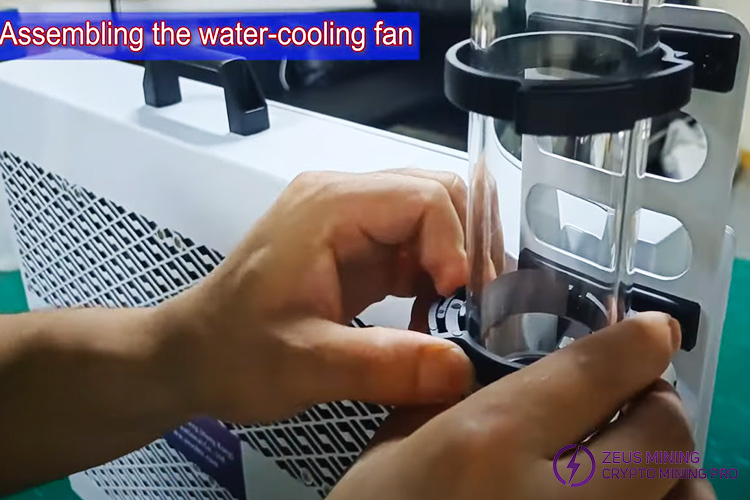

7. Connect the cables, insert the 4pin fan speed simulators plug to the fan interface of the control board to simulate fan speed.

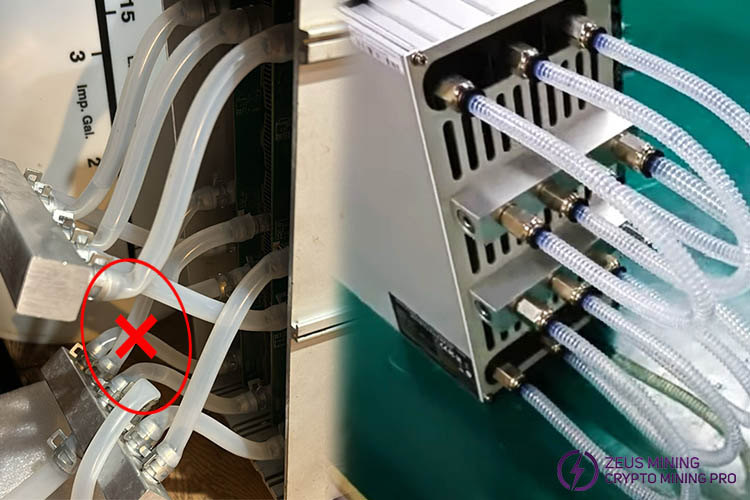

8. Fix the two water distributors to the fan baffle, install the baffle at the air outlet of the miner, then connect the water cooling plate to the water distributors with corrugated pipes (each water distributor will remain 1 interface for connecting to an external radiator). Ensure that the connections are tight to avoid water leakage.

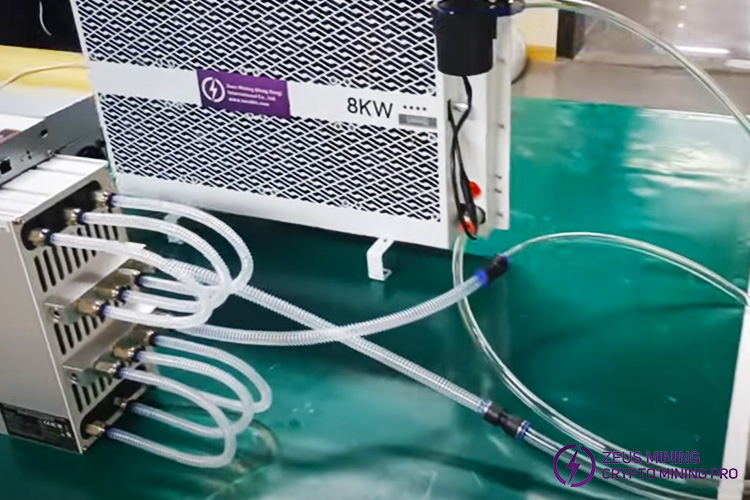

9. Use screws to fix the bottom bracket of the radiator to keep the radiator stable. Install the water pump bracket and fix the water pump on the Lianli 8KW integrated universal water cooling radiator.

10. Use water pipes to connect the water outlet of the external radiator's water pump to the upper water distributor, then connect its water inlet to the lower one. Ensure that the connections are also tight.

11. After all water pipes and fittings are securely connected, add coolant to the radiator water pump until the water level no longer drops. Power on the radiator, continue adding coolant until the water level no longer drops, and the highest water level is about 5cm from the top of the pump.

12. Power on the miner to test its operating status.

Note: To prevent air bubbles and damage to the pump, it is recommended to fully insert the water inlet pipe into the pump when installing the pump.

(Water cooling example diagram)

Note: After completing the water cooling modification of the miner, it is necessary to regularly check the water cooling system and add coolant in time.

By introducing an efficient water cooling system, we have effectively solved potential problems caused by high temperatures, not only reducing the failure rate of the miner, improving mining efficiency, but also extending the service life of the machine. In addition, the water cooling system also brings a quieter and more comfortable working environment, making the mining journey more enjoyable.