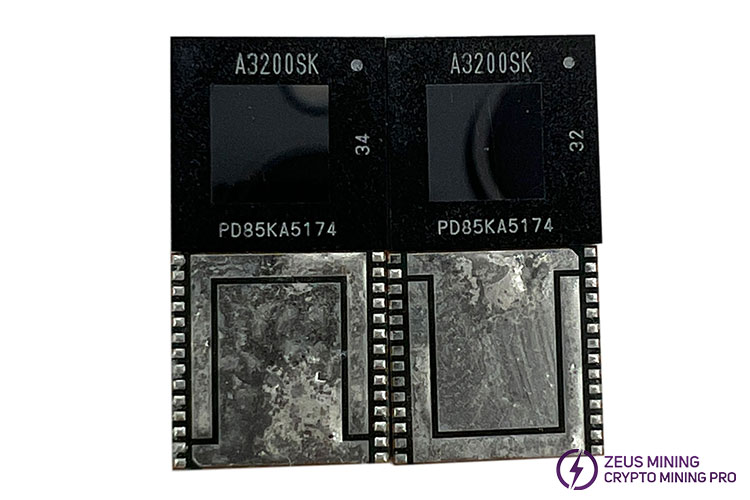

The A3200SK ASIC chip is designed for replacing faulty ASIC chips on the 1166 hash board. Utilizing advanced semiconductor technology, it boasts a high hash rate and low power consumption. Through optimized architecture and design, it improves data processing speed and energy efficiency ratio, enabling higher hash rates at lower energy consumption. It is suitable for large mining farms and professional mining equipment, serving as one of the essential hardware in the current cryptocurrency mining market.

Faults in the Avalon A3200SK ASIC chip can lead to issues such as decreased hash rate, frequent reboots, overheating alarms, connection problems, increased error rates, equipment downtime, and power supply issues. These indicate hardware or software failures, requiring prompt inspection, replacement, and repair to restore the miner's normal operation.

Detailed steps for replacing the ASIC chip on the Avalon 1166:

Tools required: screwdriver, anti-static insulation pad, constant temperature heating platform, tweezers, magnifying glass, circuit board cleaner, dust cloth, soldering flux, tinning tools, tin paste, etc. In addition, use other appropriate tools according to personal needs.

Desoldering the faulty chip:

1. Cut off the powering to the miner and wait for it to cool down internally. Remove the protective shell and detach the cooling fan.

2. After step 1, we can see the internal structure of the miner. Take out the faulty hash board, place it on the anti-static insulation pad, and disassemble the heat sink on the hash board.

3. First, determine the location of the faulty chip and clean the area around it.

4. Apply soldering flux to the chip pins, turn on the constant temperature heating platform, and heat it to approximately 300℃. Place the hash board in the area where the faulty chip is located face up on the heated platform. The temp of the heating platform is very high, so be careful during operation to avoid scald.

5. The solder on the chip pins will gradually melt with heat. Use tweezers to clamp and take out the chip.

6. Remove the hash board from the heating platform, which will be hot. Allow it to cool down, then use a cleaner to clean solder residue.

Soldering a new Avalon A3200SK ASIC chip:

1. Before soldering the new chip, its soldering surface is free of tin, which is not conducive to good soldering. Therefore, we need to tinning the new A3200SK chip.

2. Apply an appropriate amount of soldering flux to the pad where the faulty chip was removed. If there is not enough tin, we can add an appropriate amount.

3. Maintain the same temperature on the heating platform as when Desoldering the faulty chip, heating until the solder in the pad melts.

4. Align the chip's pins with the pad and continue heating until the solder paste covers the chip's pins.

5. Turn off the heating platform and use a cooling fan to cool the hash board.

6. Test the chip's signal grounding value to ensure there is no faulty soldering.

7. Apply thermal paste evenly on the chip's surface and install the heat sink.

8. Place the hash board back in the miner box, power it on, and monitor the miner's hash board operation data.

The Avalon 1166 hash board may experience abnormal phenomena after long-term operation. Causes for failures in the A3200SK ASIC chip can include overheating, unstable powering, manufacturing defects, environmental factors (such as humidity and dust), aging due to long-term high-intensity operation, and software or firmware issues. Overheating is often caused by poor heat dissipation, while power supply issues may stem from power equipment failures or voltage fluctuations. Regular maintenance and monitoring can help prevent and detect these issues promptly.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD