The temperature sensor cables are suitable for Avalon 1066Pro, 1166, and 1246 miners. They are made of high-temp and wear-resistant materials to ensure they won't easily break down during long-term high-load operation. The cables contain sensitive thermocouples or thermistors inside, which can accurately detect temp changes. The main function of the sensor cables is to collect data by absorbing temperature and transmit the obtained temp data to the control board, assisting in adjusting fan speeds and other heat dissipation measures to keep the equipment operating within an appropriate temp range.

Common symptoms of faulty temperature sensing cables:

● Abnormal temp readings, displaying extremely high or low temperatures.

● Unstable data, with frequent fluctuations in displayed temperature values.

● Electromagnetic interference generated during operation, affecting signal transmission and leading to inaccurate temp readings.

● Poor contact or loosening, resulting in interruptions in temperature data transmission.

● Automatic shutdown, with the protection mechanism triggered.

Faulty temperature sensor cables need to be replaced immediately. The specific steps are as follows:

1. Before replacement, turn off the power to the miner and disconnect the power cord to ensure personal and equipment safety during operation.

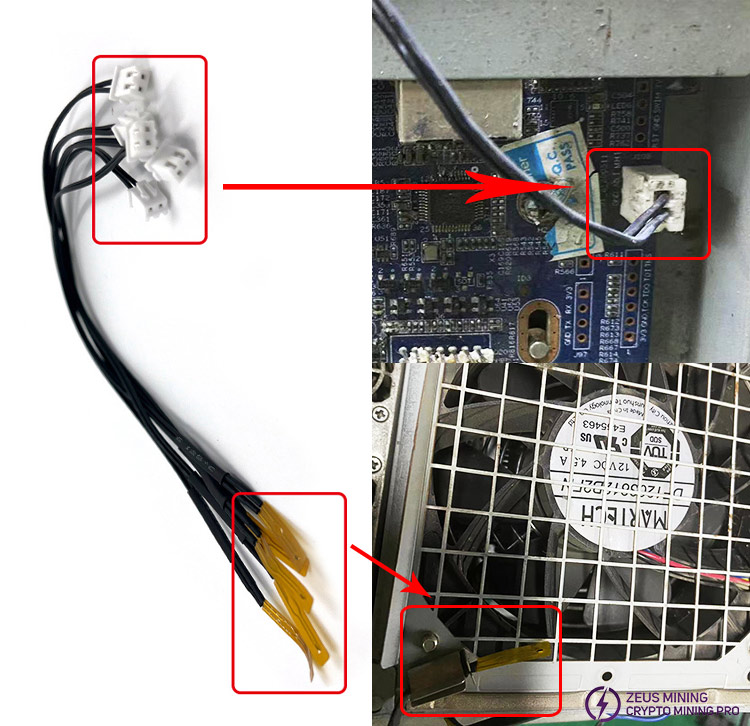

2. Disassemble the miner's protective casing and locate the temperature sensor cable connected to the control board and air inlet.

3. Carefully disassemble the faulty temperature sensing cables to avoid damaging the interfaces.

4. Connect the white end of the new temperature sensor cable to the control board interface, and fix the yellow flat end at the temperature monitoring point required at the air inlet.

5. Ensure the connections at the interfaces are secure, turn on the miner again, check if the temp readings have returned to normal, and ensure the new cables are working properly.

Maintenance and care: Regularly check the connections and status of the temperature sensor cable to ensure there are no breaks or wear. Avoid using corrosive or conductive cleaning agents during cleaning to prevent affecting the accuracy of the sensors and the safe operation of the miner.

Replacing temperature sensing cables ensures accurate temp monitoring, helps miners avoid overheating while operating efficiently, improves operational stability, and extends equipment lifespan. Properly functioning temperature sensor cables can promptly feed back temp information, helping miners take protective measures in case of temperature abnormalities to prevent unexpected shutdowns or damage.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD