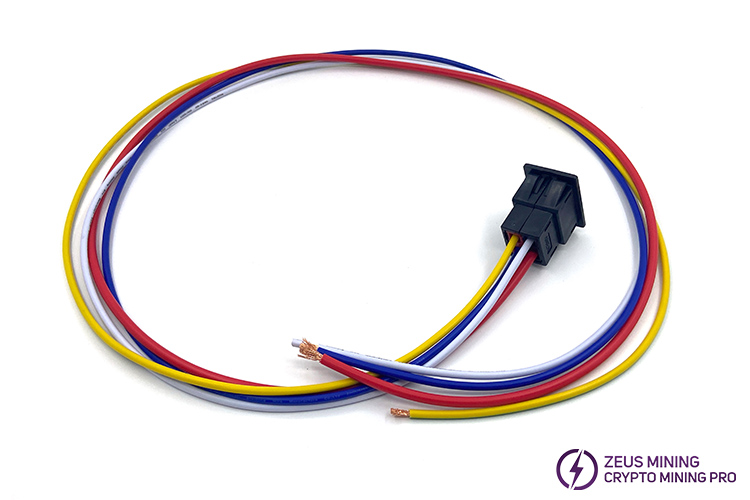

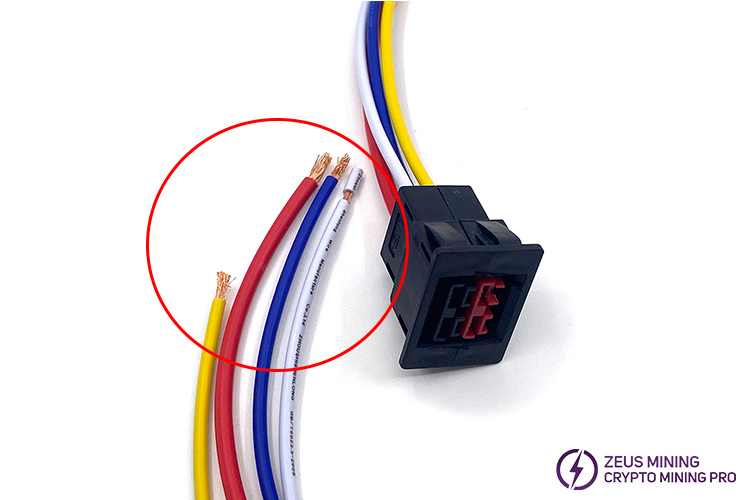

The Whatsminer Hydro single head socket power cord, with a 4-pin design, adopts advanced manufacturing technology and is equipped with a water cooler as PDU. It is suitable for most water-cooled series host models, such as M34S+, M33S, M33S+, M33S++, M53, M53S, M53S+, M53S++, M63, M63S, M66, M66S, and other miners. Its main purpose is to ensure normal powering for the equipment.

PSU cord failures can directly lead to miner downtime, affecting mining revenue, then potentially damaging the equipment. They can also pose safety hazards such as electric leakage and short circuits, seriously threatening the stability and safety of mining operations, resulting in economic losses. It is crucial to replace faulty PSU cords immediately.

Guide to quickly replacing damaged PSU cable:

1. Disconnect the power to the miner and PDU air switch to ensure safe operation.

2. Gently remove the faulty PSU cable to avoid damaging the interfaces on the power supply unit and PDU socket.

3. Prepare a new Whatsminer Hydro PSU cord, confirming that the model is correct and the cable is intact.

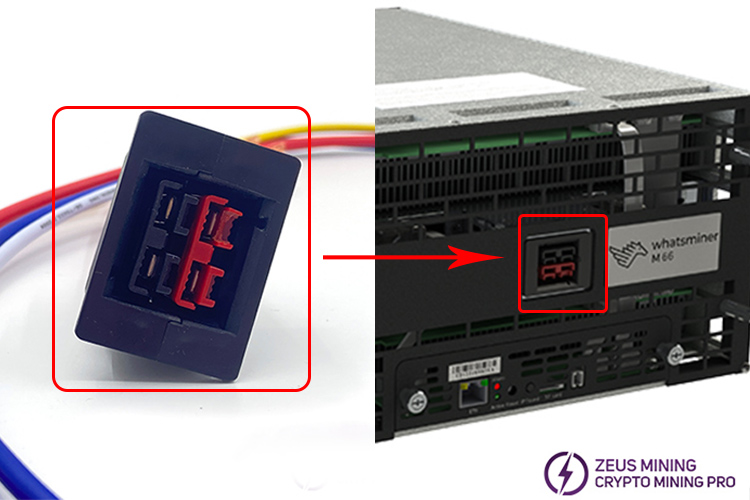

4. Connect the end of the new cable with the black plug to the miner's power interface.

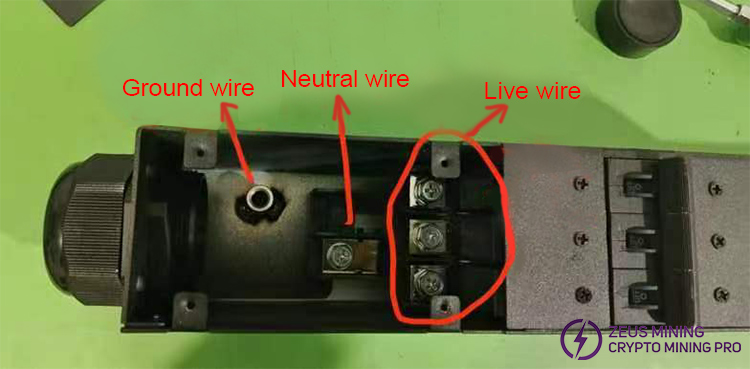

5. Using a tool or manually, wrap each wire core of the 4-wire end in sequence onto the PDU air switch interface.

6. Install the insulating protective shell to protect the wiring and prevent electric shock hazards.

7. Ensure the connections are secure, turn on the miner, then check if the powering has been restored.

Precautions and cable maintenance:

1. Daily inspection of the PSU cable for completeness, checking for damage, breaks, or exposed parts. Use a voltage tester to ensure it is not energized during maintenance or replacement.

2. Regularly check the insulation layer of the cable for aging, cracking, or wear. Pay special attention to overheating of the power cord during miner operation to prevent damage to the insulation layer.

3. Ensure that the PSU cord is securely connected to the miner, socket, and other connections, with no looseness. Check for oxidation or corrosion at the connection points and clean or replace them if necessary.

4. Monitor the temperature and humidity of the power cable and surrounding environment during miner operation to prevent overheating and moisture damage that could lead to electric shock. If necessary, use temperature sensors and other equipment to monitor the power cord temperature in real time.

5. Record the daily maintenance of the power cable, including inspection time, inspection results, and handling measures. Report any abnormalities to relevant technical personnel for prompt handling.

Replacing the Whatsminer M53 Hydro PSU cord can enhance equipment stability, ensure equipment safety, improve mining efficiency, and extend miner lifespan.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD