The DES H93B is a three-in-one intelligent temperature-controlled desoldering station for repairing the hash board, control board, and power supply. Different from traditional desoldering stations, it integrates an electric soldering iron, a hot air gun, and a smoke purifier, which can meet the soldering needs of different scenarios. At the same time, the newly added smoke absorber effectively prevents harmful gases generated during component replacement from entering the human body, making the soldering work safer and more efficient.

Now, let's have a detailed understanding of the functions and usage methods of the DES H93B desoldering station:

Functions:

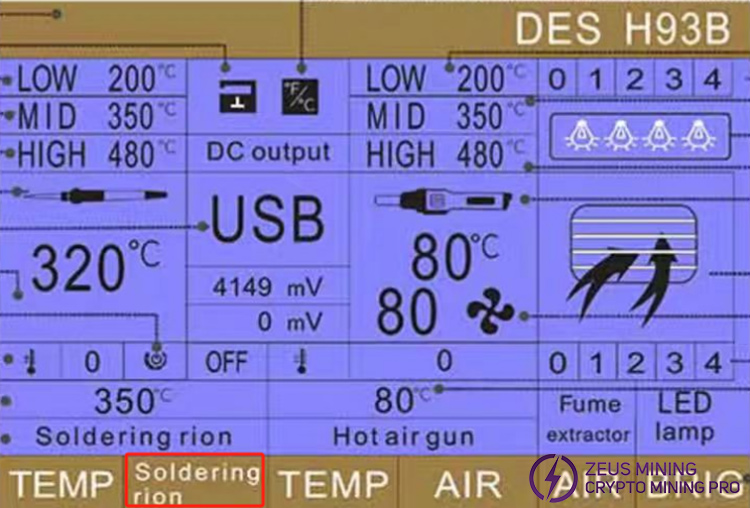

1. Intelligent large-screen display, microcomputer control, smooth operating system, and the large screen displays the working status in real-time.

2. The air purifier has an LED light with 4 gears of brightness, making soldering more convenient.

3. The smoking nozzle uses carbon ion filtration, multiple filtrations, and purification layer by layer, which can easily filter toxic substances such as dust, CO, methanol, and tin wire.

4. High-precision soldering iron tip, precise maintenance without damaging components.

5. Adopts a multifunctional soldering iron base with a plug-in buckle design, enabling one-handed rapid replacement of the soldering iron tip.

6. The hot air gun adopts a touch-sensitive design. You can start working by holding the sensing area, and it enters the sleep state when you release your hand.

7. Intelligent cooling. It automatically supplies air for cooling after stopping use, eliminating hidden dangers and being safer.

Usage methods:

1. First, we need to understand the functions of each button on the host.

2. Select the corresponding soldering tool according to the components that need to be soldered, and then install the air nozzle or soldering iron tip on the corresponding handle.

3. Connect the handle plug to the corresponding socket interface of the host.

4. After power-on, turn on the power switch, find the control button corresponding to the selected soldering tool, subsequently, press and hold to enter the adjustment function. The three-speed quick key can be used for rapid adjustment, and then the function key encoder for fine adjustment. Press the function key to confirm after setting. The quick key button descriptions are as follows:

① F1: Electric soldering iron temperature adjustment button

② F2: Function button for converting between the electric soldering iron and hot air gun. When the letter "H" is displayed in the position shown in the figure below, we can adjust the hot air gun; when the letter becomes "S", we can adjust the electric soldering iron.

③ F3: Hot air gun temperature adjustment button

④ F4: Hot air gun air volume adjustment button

⑤ F5: Smoke filter air volume adjustment button

⑥ F6: LED light brightness adjustment button

5. Desoldering components

(1) Hot air gun soldering method: Select the appropriate temperature and air volume, aim the air nozzle at the component pins or solder joints that need to be soldered or desoldered, maintain an appropriate distance (usually 2 - 5 cm), and stop heating after the solder joints are completely melted.

The hot air gun is suitable for desoldering work on large areas such as multi-pin integrated circuits and surface-mounted components, such as ASIC chips, temperature sensing modules, power supply modules, etc.

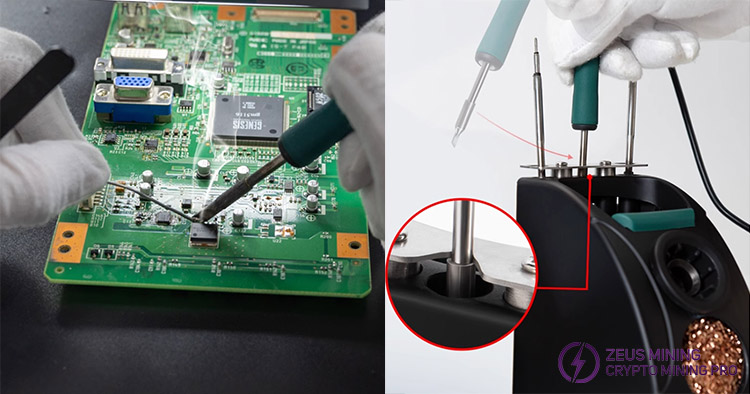

(2) Electric soldering iron soldering method: Select the appropriate temperature, first apply an appropriate amount of solder on the soldering iron tip after preheating, then contact the soldering point to melt. It is necessary to control the soldering time to prevent the solder pad from falling off or damaging the components due to overheating.

The electric soldering iron is more suitable for soldering components with fewer pins and smaller solder joints, such as resistors, capacitors, transistors, etc. When spot soldering or touch-up soldering on fine electronic components, the electric soldering iron can provide more precise control.

The DES H93B intelligent temperature-controlled desoldering station, with its precise temperature control and convenient operation mode, provides an efficient and reliable solution for the replacement of the miner's components, helping to extend its service life and ensure stable profits from mining.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD