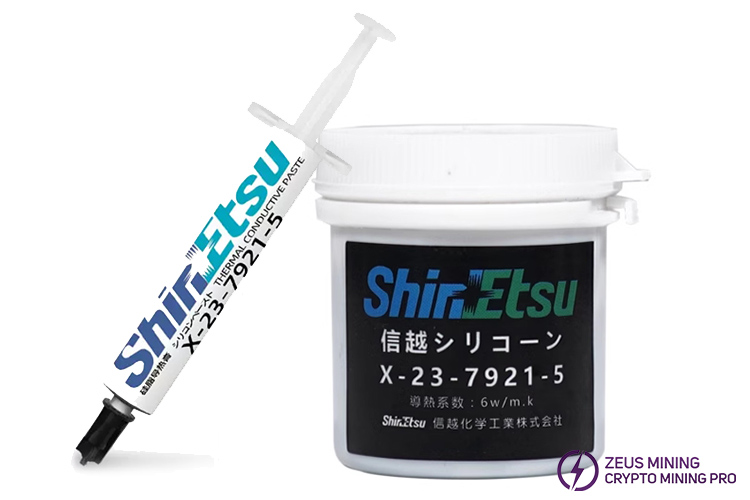

X-23-7921-5 thermal grease is a kind of thermal material with excellent thermal conductivity. Its paste is gray and the thermal conductivity coefficient is 6.00W/m·K, which can be used in the temperature range from -50°C to +120°C. It effectively fills the tiny gaps between ASIC chips and heat sinks, helping the miner to quickly dissipate the heat generated during operation, providing a reliable guarantee for stable mining and prolonging its service life.

X-23-7921-5 thermal paste has multiple specifications to choose from, which can be selected according to the actual needs, efficiently avoiding problems such as paste drying and thermal conductivity reduction due to long-term non-use after opening.

Thermal grease is often used for faulty ASIC chip replacement or water-cooled modification of miners. In addition, the mining farm managers should regularly check and replace the thermal grease to ensure the best heat dissipation efficiency.

How to use thermal grease?

1. First, disassemble the miner, remove the corresponding parts, unplug the cables, and then take out the hash board from the case.

2. Remove the heat sink on the front of the hash board. Use circuit board cleaning liquid and sponge to clean the circuit board.

3. How to use the canned version?

a. Select the grease template corresponding to the miner model, place it on the front of the hash board, and ensure that all holes are completely aligned with the ASIC chips, preventing the grease from smearing to areas other than the chips.

b. Take an appropriate amount of thermal paste, subsequently, apply it in the center of the template, then spread it evenly to the surroundings with a scraper, forming a thin layer about the thickness of A4 paper.

c. Gently remove the template, after that check the application of the thermal paste. If there are bubbles, impurities, uneven smearing, etc., slightly adjust it with the scraper.

( Use of syringe version: Apply the thermal grease evenly to the surface of the ASIC chip.)

4. Reinstall the heat sinks and then put the hash board back into the miner case.

5. Install the previously removed parts in their original positions and connect the corresponding cables.

6. Power on the miner to observe its operating status through the background log.

While replacing the faulty chips, apply the thermal paste on the surface of the new chips evenly without using the grease mold. If both sides of the hash board need to be modified to the water cooler, the smooth surface of the back water-cooling plate needs to apply the thermal paste evenly, ensuring more efficient heat dissipation.

High-quality X-23-7921-5 thermal grease effectively avoids the risks of performance degradation, faults, and even burnout caused by overheating of the miner, further extending the machine's service life, and providing a reliable guarantee for obtaining stable returns.

Dear Customers,

Hello, April 4, 5 and 6, 2025 (GMT+8) are the traditional Chinese festivals - Qingming Festival. Our company will suspend shipments during these 3 days and resume shipments on April 7 (GMT+8). We are deeply sorry for the inconvenience. Thank you for your understanding and support.

Best wishes,

ZEUS MINING CO., LTD