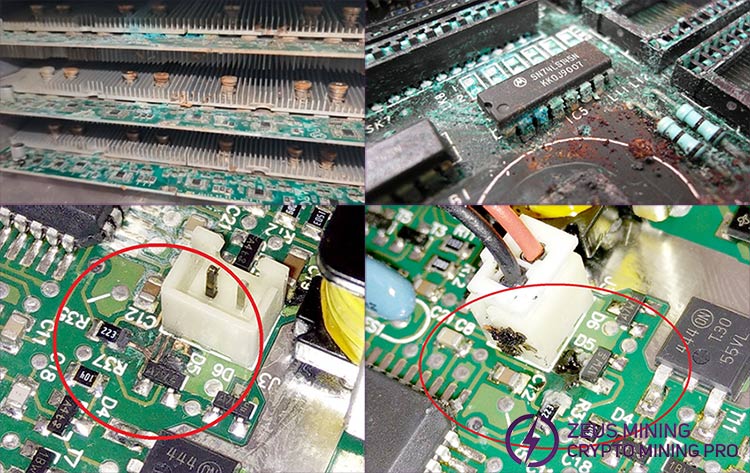

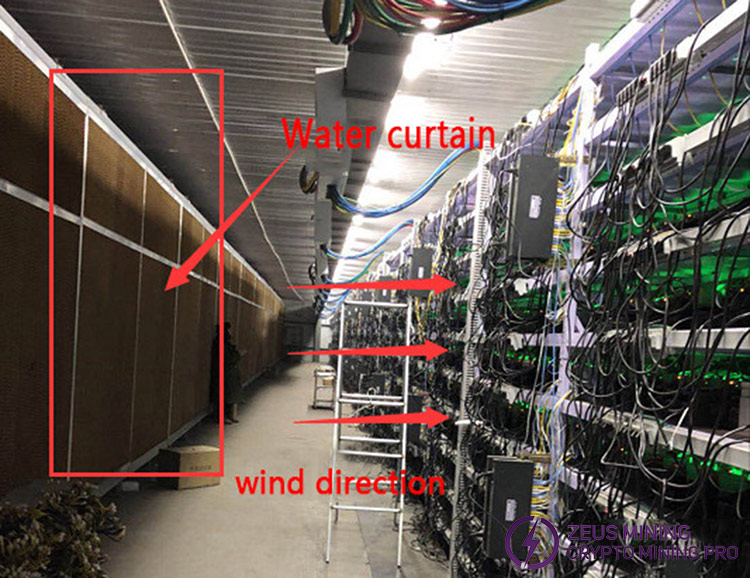

As an important tool for mining cryptocurrencies, the performance and stability of miners have attracted much attention. However, in some coastal areas, some mining farms are facing the challenge that air-cooled miners are suffering from severe corrosion. The root cause of this problem mainly lies in the fact that the environment with high humidity and high salinity poses a direct threat to electronic components. Mining farms often use water curtains for cooling, which, on the contrary, aggravates the environmental temperature and humidity, forming a vicious cycle that is prone to corrosion. The accumulation of dust also interferes with the operation of mechanical parts. Acting in combination with the moisture in the air, it impairs the performance of miners over a long period and is prone to causing malfunction issues. This article will explore solutions to this problem.

Solutions:

A. For the regulation of environmental humidity, it is necessary to maintain the humidity range of 60% - 65%. Keep a distance of at least 3 meters between the water curtain and the air inlet of the miner, and reduce the operation frequency of the water curtain. By improving heat dissipation or ventilation to reduce the dependence on the water curtain, ensure the stability of the equipment and reduce the corrosion risk.

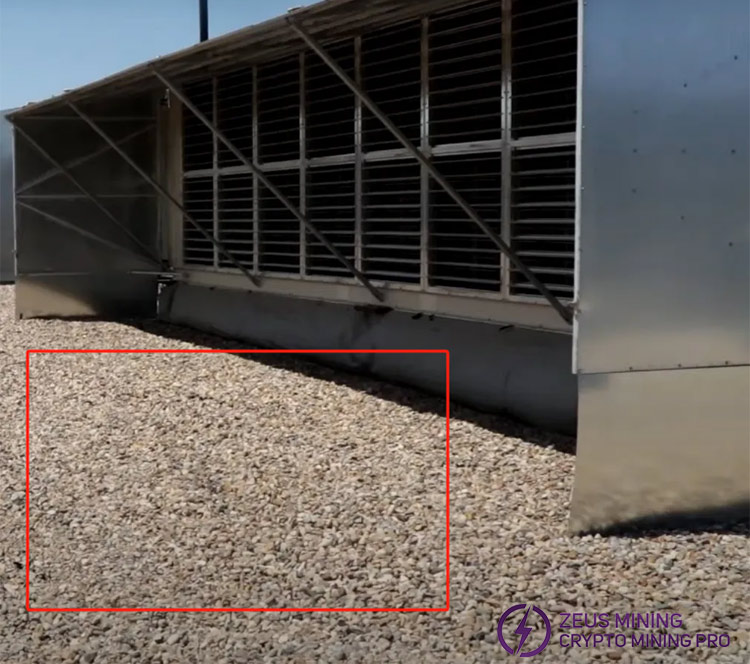

B. Adopt a double-layer dust filtration design to enhance the dustproof efficiency. Keep a distance of at least 2 meters between the dustproof equipment and the water curtain to prevent the influence of water vapor. Cover the bare soil with small stones to effectively reduce dust pollution.

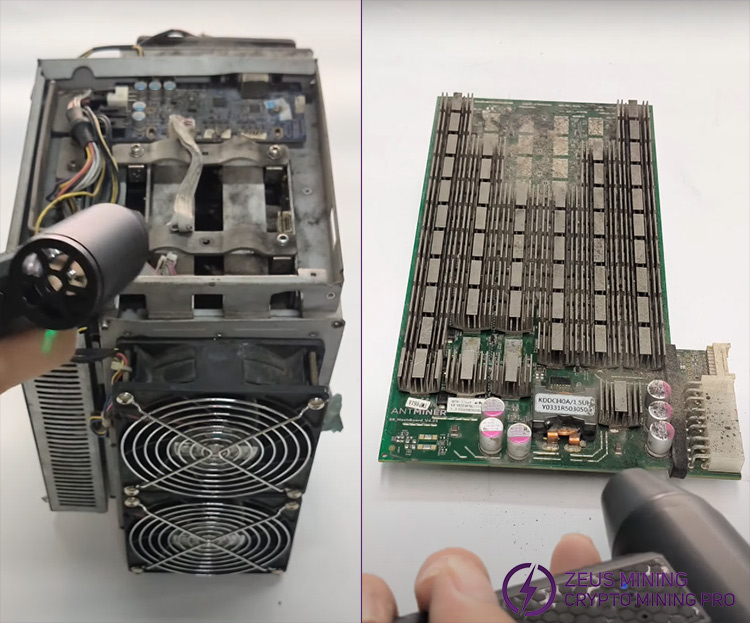

C. Conduct regular dust removal and maintenance. It is necessary to clean the dust after the miner has been running for 3 - 5 months to prevent the accumulation of dust from accelerating corrosion and keep the components clean. We can use F8 Mini Turbo Violent Fan or Anti-static Cleaning Brush Kit for cleaning.

D. Optimize the heat dissipation layout, increase the spacing between miners to 20 - 30 cm or more, isolate the heat sources of the equipment, and separate the heating and heat-sensitive components. Strengthen ventilation by adding more fans and building an efficient cooling air flow system. Ensure the free circulation of air, prevent local overheating, and improve the heat dissipation efficiency and system stability.

E. Optimize the external structure of the miner. It is necessary to reduce gaps and strengthen the sealing to isolate dust. Apply anti-corrosion techniques to key parts to improve the corrosion resistance performance.

In response to the corrosion problem of air-cooled miners, we should promptly identify the causes of corrosion and take improvement measures and adopt reasonable solutions to ensure the stable performance of mining equipment.

Disclaimer:

This article is for sharing only. For more solutions to solve the corrosion of miners, please refer to other official information. This website will not be responsible for any actions taken by readers based on this article.