For the repair of the internal electronic components of ASIC miners, solder paste, as an indispensable material in the soldering process, has its quality and performance directly related to the reliability of soldering. The following content will introduce the storage methods, usage methods and precautions during the use of solder paste, aiming to help operators better master the management skills of solder, thereby improving the efficiency and quality of soldering work.

I. Storage methods of solder paste

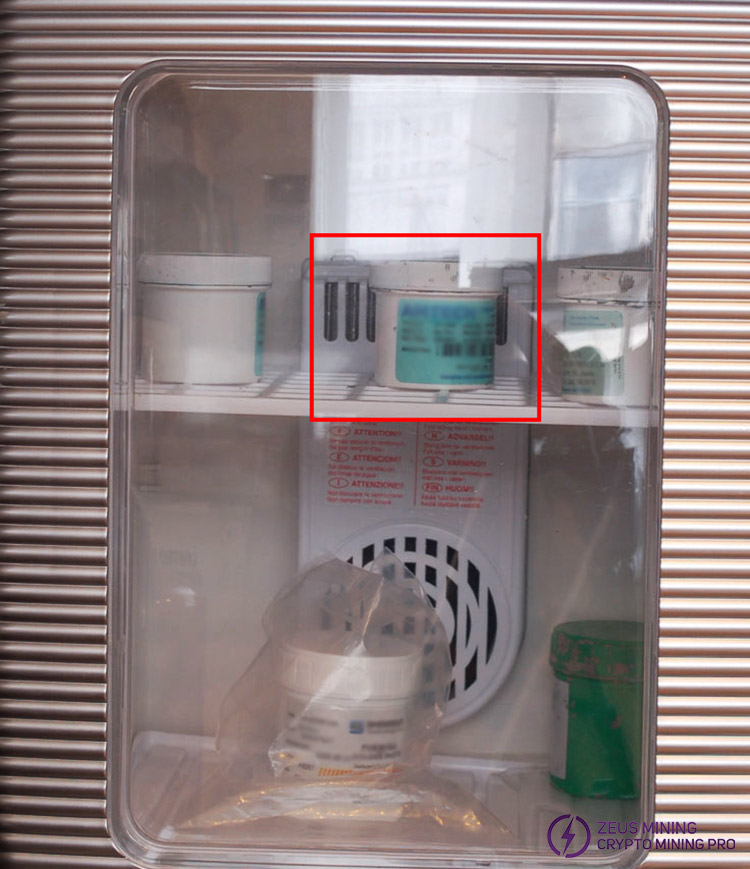

1. Store it in a refrigerator or a low-temperature container, with the temp controlled within the range of 0°C-10°C.

2. The shelf life of unopened solder paste is 6 months.

3. Avoid light exposure. The solder should not be placed in areas exposed to sunlight.

4. Before use, the solder paste needs to be warmed up at room temperature for 3-4 hours to prevent condensation.

5. For the opened solder that has not been used up, it is recommended to seal it and put it in the refrigerator for refrigeration, and try to avoid leaving it in a normal temp environment for a long time.

II. Usage methods

1. Long-term unopened solder paste needs to be thoroughly stirred evenly before use, and the stirring time is generally 3-5 minutes.

2. The amount of solder taken out from the cold storage each time should not be too much. Take it as needed to avoid waste and reduce the chances of oxidation and contamination.

3. The taken-out solder paste should be used as soon as possible. The unused solder should be sealed and refrigerated and should not be mixed with new solder paste.

4. In case of the solidification of solder paste, it can be diluted with SMT solder paste thinner and then used to achieve the same effect.

5. The environmental temperature for solder paste printing and use should be controlled within 22-28°C, and the humidity should be RH 30-60%.

6. After the solder is taken out, it should be printed immediately and keep continuous printing without interruption to ensure the printing quality.

7. After using the solder paste, it is necessary to clean up the remaining solder dross and keep the working environment clean.

III. Precautions

1. Try to shorten the opening time of the solder paste. After taking out enough solder, seal and cover it immediately.

2. Follow the principle of "first in, first out" and give priority to using the solder paste that has been stored for a longer time.

3. Operators should avoid direct contact between solder and skin. If accidentally contaminated, wash it immediately with soap and water.

4. The shelf life of solder paste produced in different places may vary. For more specific information, please follow the user manual when purchasing the solder paste or the suggestions given by the manufacturer.

Solder paste is available in three types: high-temp, medium-temperature, and low-temp, their application ranges and soldering effects are also different. Click here to view the differences of solder paste. If you need to use solder, you can click Maintenance soldering materials to select it.

Correct storage and usage methods can maintain the performance and service life of solder paste without shortening them, keep the solder in the best condition, and provide a reliable guarantee for soldering work.