Antminer APW17 1215a Power Supply Repair Guide

Ⅰ. Maintenance platform requirements

1. Constant temperature soldering iron 80W or above (soldering temperature is 300-350℃). The pointed soldering iron tip is used for soldering SMD components such as chip resistors and capacitors, and the knife-shaped soldering iron tip is used for soldering and replacement of plug-in components (soldering temperature is 380-420℃).

2. The hot air gun is used for chip disassembly and soldering. Be careful not to heat for a long time to avoid PCB blistering (welding temperature is 260℃±2℃).

3. The AC controllable PSU voltage regulator (output 200-300V, current limit 0-30A) is used for APW17 power-on inspection. If conditions permit, we can also use the mains power to string a 100W ordinary light bulb in the AC live wire, and pay attention to safety when controlling the circuit breaker.

4. Electronic load (power 4KW, voltage 0-50V). If there is no condition, power resistance load (15V/260A) matching APW17 can also be made.

5. Multimeter, suction gun, tweezers, ZJ0001000001 or V9 1.2 test fixture plus special PSU test card firmware (if conditions permit, an oscilloscope can be configured).

6. Flux, lead-free tin wire, board washing water plus anhydrous alcohol; board washing water is used to clean the flux residue and appearance after maintenance.

7. High-voltage insulating thermal conductive silicone grease (2500) is used to repair the heat conduction between MOS and the heat sink. Protective silicone (704 silicone) is used to fix and cover the damaged original glue point of PCBA components after repair.

Ⅱ. Maintenance work requirements

1. Maintenance personnel must have certain electronic knowledge, more than one year of maintenance experience, a certain understanding of the working principle of switching power supplies, and proficient installation and welding technology.

2. Before the product shell is opened to repair the PCBA board, the large capacitor must be discharged. After measuring with a multimeter that there is no voltage (discharge is completed below 5V), welding work can be carried out! Pay attention to confirmation to avoid electric shock.

3. Pay attention to the operation method when judging the circuit components. After replacing any device, the PCB board has no obvious deformation, the pad welding is reliable, and check whether there are open circuits and short circuits in the replaced parts and the surrounding parts.

4. After replacing the key components, the main circuit is checked and measured to have no short circuits and other obvious abnormalities before the AC voltage test can be performed, otherwise there is a risk of explosion.

5. When AC220V voltage is needed to determine the circuit signal, pay attention to operational protection.

Notes on power supply maintenance:

1. The qualifications of maintenance personnel must meet the specified requirements;

2. The instruments and equipment used for maintenance must meet the specified requirements;

3. The instruments and equipment to be maintained must be effectively grounded, and the maintenance environment requirements must comply with the anti-static requirements;

4. The materials used for maintenance must meet the specified requirements. In order to ensure the accuracy and traceability of the materials used for maintenance, the materials used for maintenance must be the production materials of the corresponding model, and the material replacement requirements must be confirmed;

5. To prevent the possible risk of electric shock, non-professionals should not disassemble the casing;

6. When maintenance personnel open the casing of the power adapter for maintenance, they are required to use a special casing opening machine to avoid damaging the internal components of the product;

7. After the product is opened, the high-voltage capacitor is required to be discharged;

8. The electronic waste fertilizer generated during product maintenance cannot be discarded at will;

9. Defective products must have a maintenance process card to identify the cause of the defect and be placed in different areas;

10. Repaired products must be marked to distinguish them;

11. Repaired products must be placed in the repaired area and require systematic testing before they can be put into storage.

III. APW17 1215a power supply principle and structure

1. Principle overview

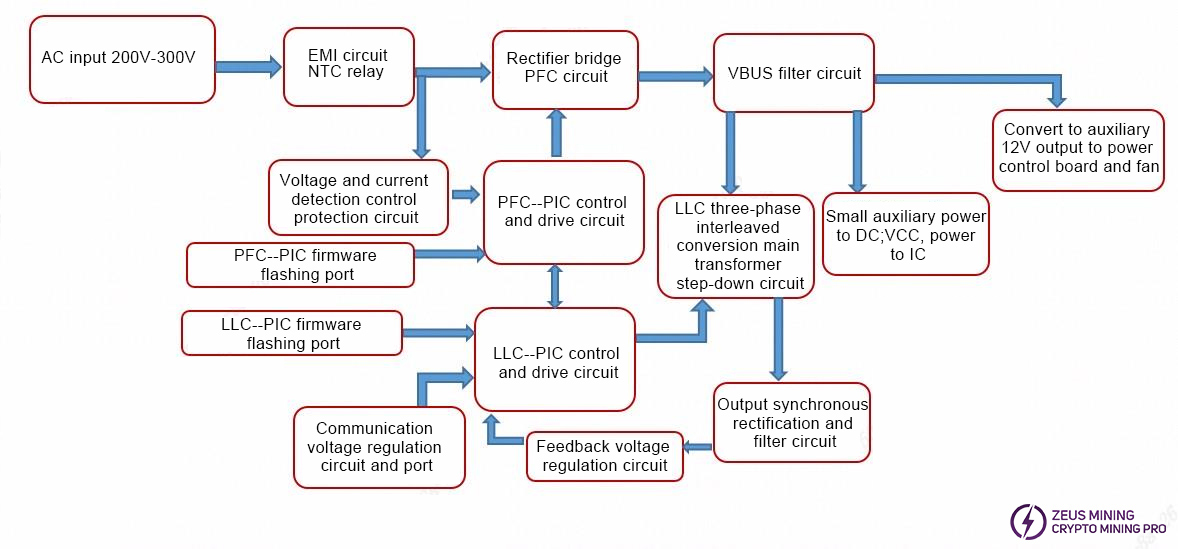

1.1 APW17 consists of 1 large board, 3 60mm fans, upper and lower shells. The normal input is between AC200V-300V and there are two DC output voltages, SB 12V and the main voltage output 12V-15V, which are controlled by PIC port and miner communication.

1.2 Performance characteristics and scope of use are as follows:

APW17 power supply is a high-efficiency DC power supply with single-phase AC two-way input and two-way DC output:

(1) 12V-15V voltage output is adjustable, and the maximum current can reach 12V/320A; 15V/267A

(2) The auxiliary terminal has a fixed output of 12V voltage, and the current can reach 18A.

The adjustable voltage output part can meet the use of common DC loads within the adjustable voltage range of 267A, especially suitable for servers and mining machines with strict power requirements; the 12V fixed voltage output part can meet the use of control boards and cooling fans.

1.21 APW17 1215a has the following features:

(1) AC200-300V wide voltage input.

(2) Built-in undervoltage, short circuit, overload, and overtemperature protection, which can automatically recover after the fault is removed.

(3) The selection of high-quality components ensures the stability and reliability of the product through reasonable design, and it can work at full load for a long time in a high temperature environment within 45℃.

(4) Small size and high power density.

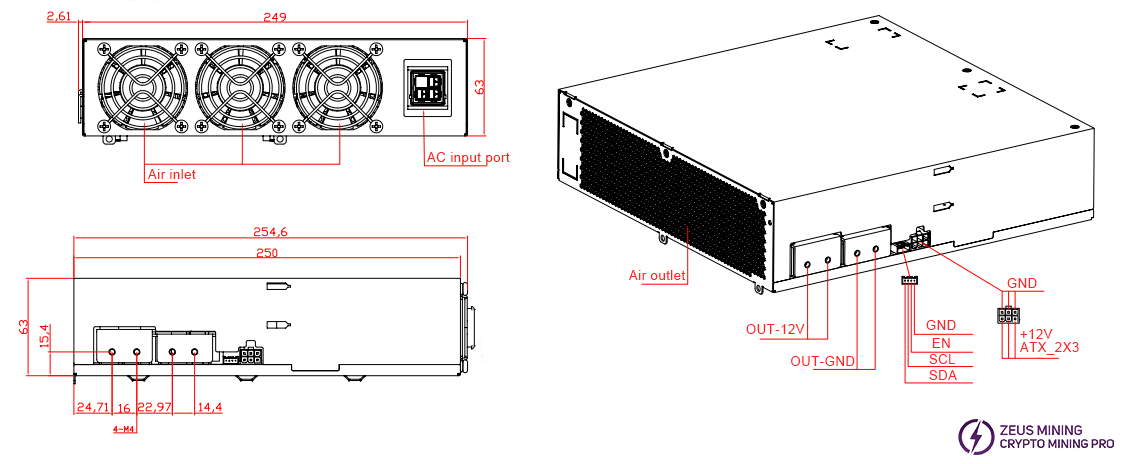

1.3 APW17 PSU appearance introduction

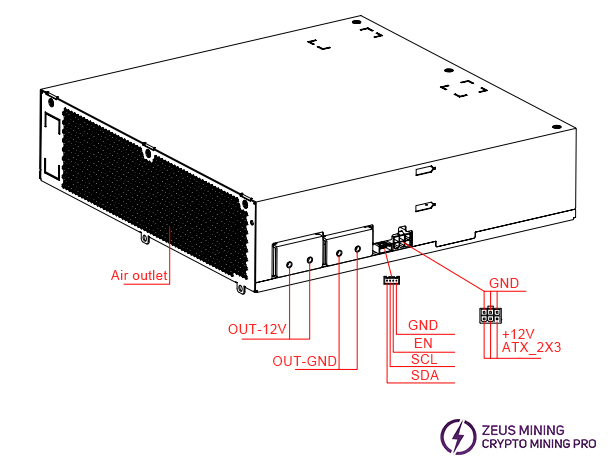

Note: If we need to test the default voltage of 15V when starting up, we can use an adapter cable to short-circuit the voltage regulator port pin EN and GND.

The actual product shall prevail. The following is the APW17 shell and input port diagram:

● Distribution on the front panel of the PSU:

(1) PA45 customized AC input interface: 1

(2) 60*60*25mm medium-speed fan: 3

● Distribution on the left side of the PSU:

(1) PCB-33 copper welding terminal with adjustable voltage output: 2

(2) 4-pin signal terminal: 1

(3) 12V fixed voltage output PCIE terminal: 1

● Distribution on the back panel of the PSU: heat dissipation outlet, forming the fan outlet.

● The model of the AC input terminal on the front panel of the power supply is "Part No. Y04280532; PA45 four-position short buckle fixing seat, AC input female seat, silver-plated contacts, L (black, OT-M4, 65mm), N (white, OT-M4, 65mm), ground wire (yellow-green, OT-M4, 60mm)", and the corresponding AC input cable is required for use (Y23160511, cable assembly_SJTW, power cable, 12AWGx3C, ANTWIRE-20SP, 1.2m, black)

● The 4Pin signal terminal is the interface for the external control board to communicate with the PSU, where SDA/SCL is the I2C protocol, and the output voltage of the power supply can be adjusted through I2C. EN is the enable signal. The control board can enable the power supply through EN, and the low level is effective.

● The adjustable voltage output part uses 2 copper strip welding terminals. The copper strip terminal near the air outlet is the output positive pole, and the one near the signal terminal is the output negative pole. The output wire or output copper strip can be fixed on the terminal by M4 screws, which is convenient and flexible to use.

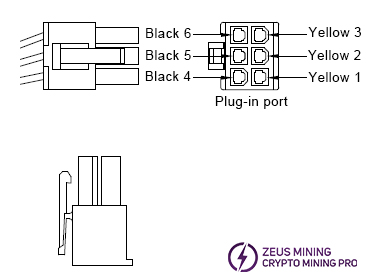

● The 12V fixed voltage output part uses PCIE output terminal. The schematic diagram of PCIE output terminal is as follows:

The PCIE output cable consists of two colors, the 12V positive cable is yellow and the negative one is black.

6PIN PCIE terminal positive and negative pole definition:

Positive: yellow 1, yellow 2, yellow 3

Negative: black 4, black 5, black 6

1.4 APW17 power supply parameter table:

OUT1 | Main output DC voltage | 12V-15V |

Rated current (220V-300V input) | DC15V/267A/ DC12V/300A | |

Rated power (220V input) | 4200W | |

Ripple and noise | <1% | |

Source regulation | <1% | |

Load regulation | <1% | |

Start-up and rise time | <2S | |

Power-off hold time | >10mS | |

OUT2 | DC voltage | 12-12.45V |

Rated current (at 220V input) | 18A | |

Ripple and noise | <1% | |

Auxiliary voltage accuracy | 12.2V---12.4V | |

Source regulation | <1% | |

Load regulation | <1% | |

Start-up and rise time | <2S | |

Power-off hold time | >10mS | |

INPUT | Voltage range | 200-300V AC (one channel) |

Frequency range | 47-63Hz | |

Power factor | >0.99 (full load) | |

Leakage current | <1.5mA (220V 50Hz) | |

Protection | Input undervoltage protection value | 180-190V AC |

Output short circuit | Yes | |

Output overcurrent protection value | 291-360A | |

Overtemperature protection | Yes | |

Environment | Operating temperature | -20 ~ 50℃ |

Operating humidity | 20% ~ 90%RH (no condensation) | |

Altitude | Less than 2000m | |

Structure | Dimensions | 254*250*63 |

Net weight | About 4Kg | |

Cooling method | Forced air cooling | |

Noise | 67dBA |

2. Power supply basic principle block diagram

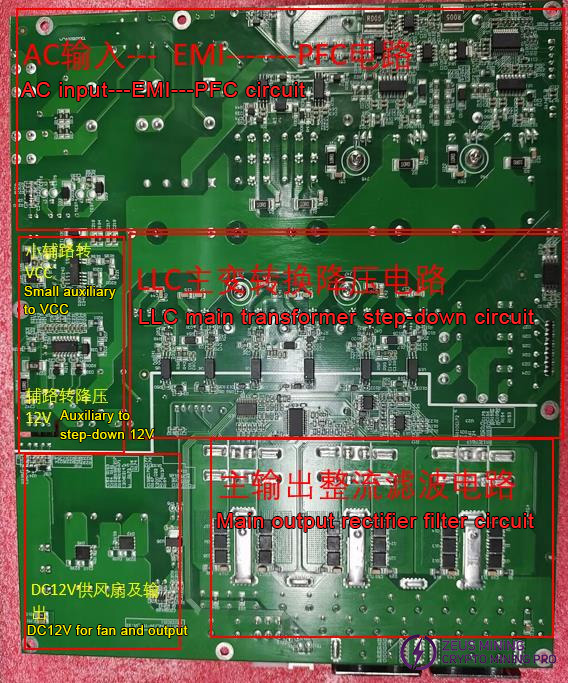

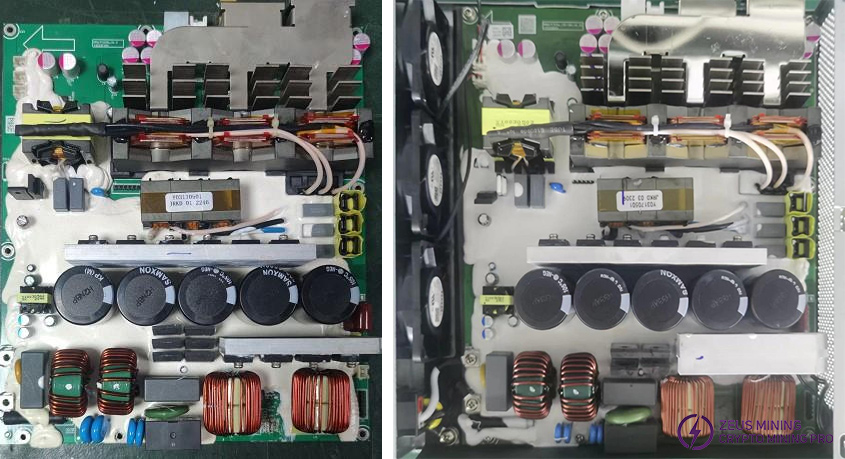

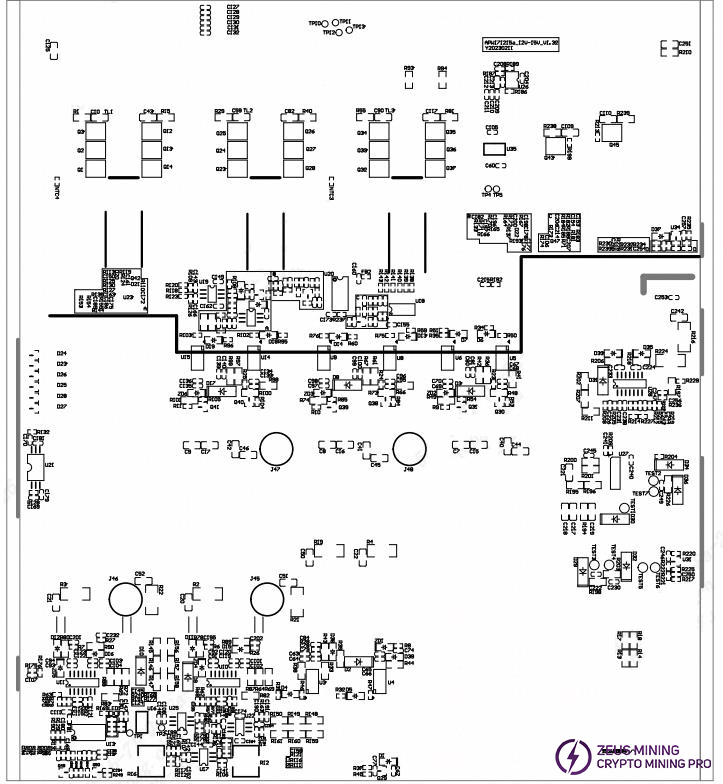

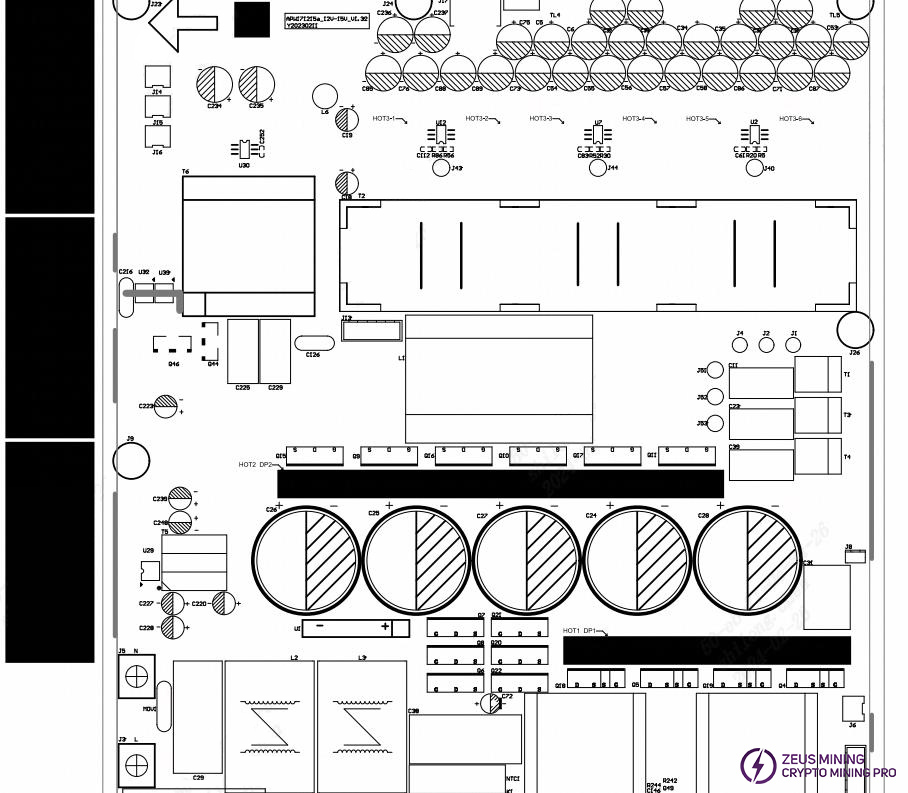

2.1 Power PCBA board layout

Layout instructions: AC input and EMI circuit--- PFC and main parallel MOS circuit, small power auxiliary and VCC circuit, 12V output port and PIC communication port main driver IC, PIC control chip---main output

2.2 Actual picture display, there will be slight differences in different product versions, but the principles are similar.

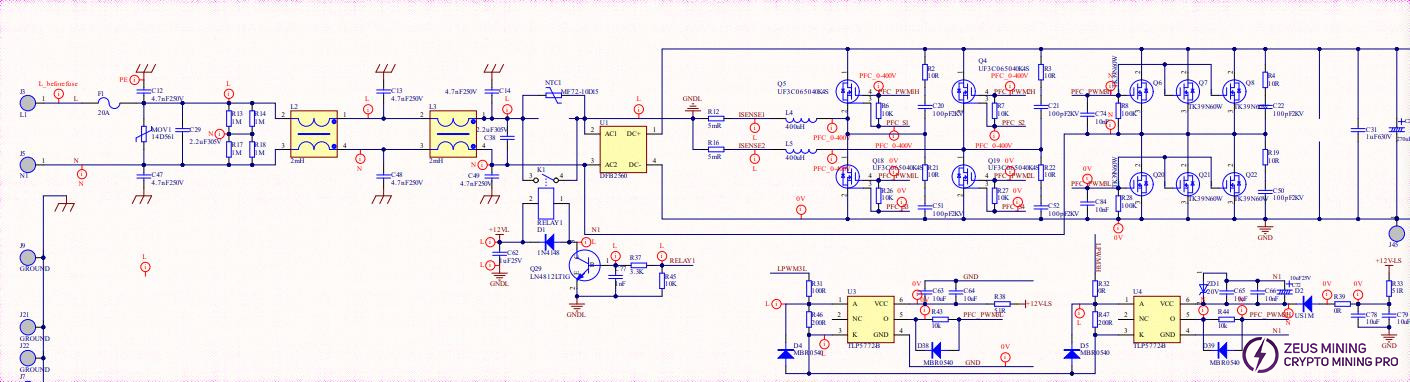

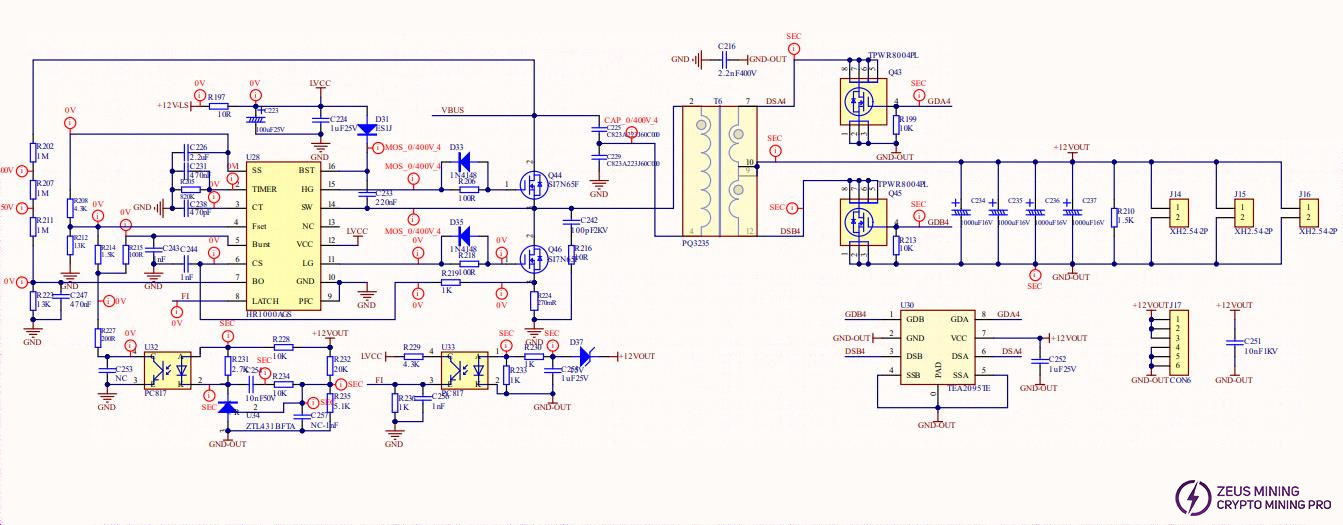

2.21 Schematic diagram of AC input EMI to PFC circuit

If the power supply has no output, focus on measuring whether F1 fuse, PFC fast tube MOS Q5, Q18, Q4, Q19, slow tube Q6, Q7, Q8, Q20, Q21, Q22 are short-circuited or damaged. Note that when MOS is damaged, it drives a small resistor; the diode and signal circuit may be damaged synchronously and need to replace U3, U4, U10, U11, etc. When working normally, it can be judged that the DC voltage across the large capacitors C24, C25, etc. is 410-430V.

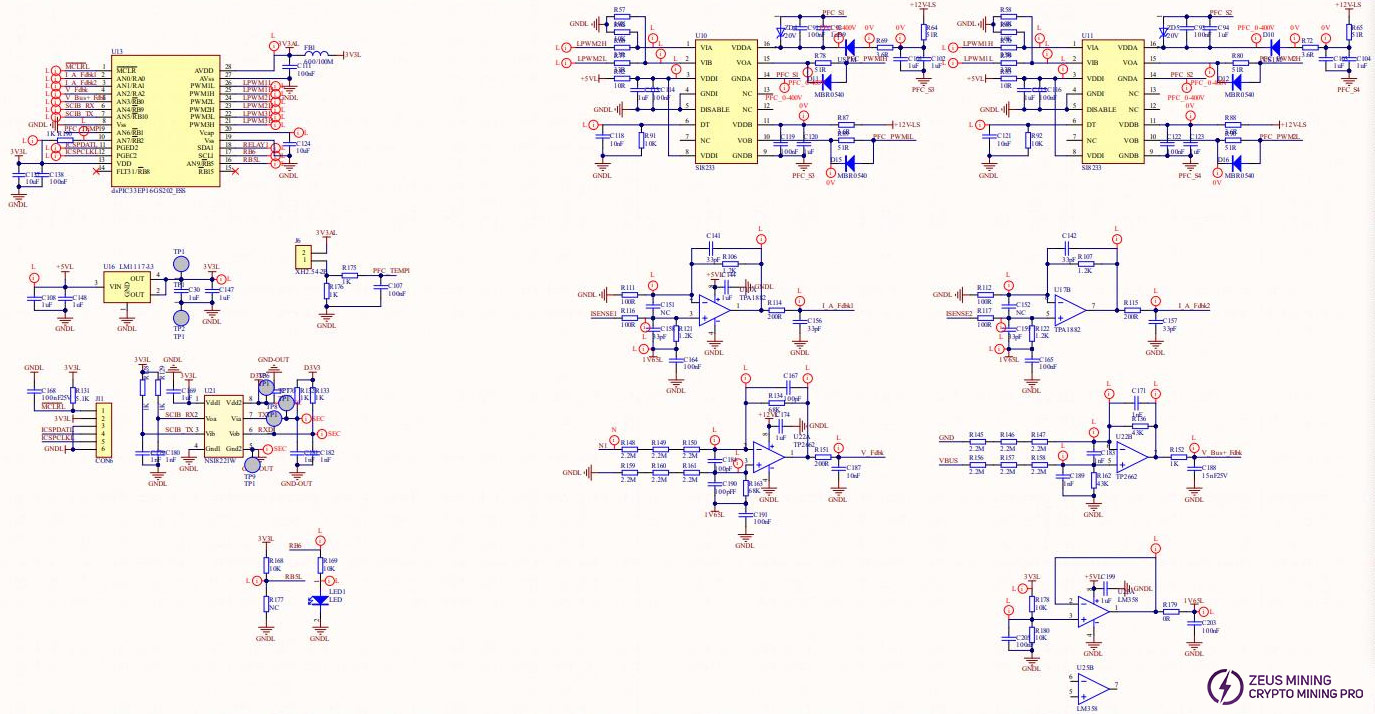

PFC drive control, detection protection, U13 PIC chip, J11 burning port:

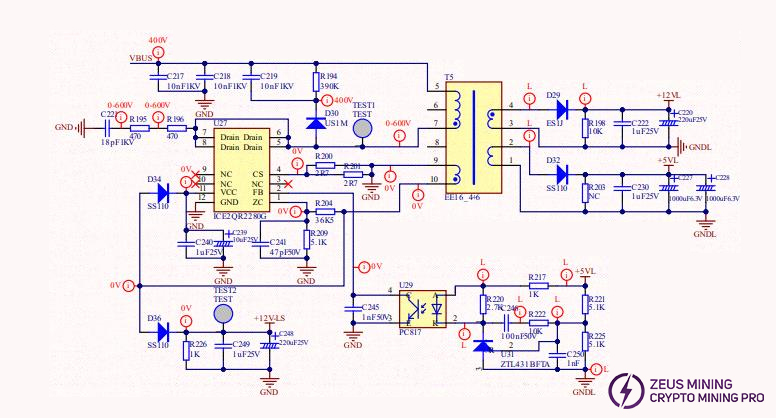

2.22 Principle of small power supply auxiliary to VCC power

Normal output of two groups of VCC 12V and one group of 5V to share power with IC components, judge that there is no short circuit abnormality. After power on, this circuit must work normally before it can power other ICs. Measure TEST2/TEST7 (11.98V-12.3V), TEST3/TEST4 (11.98V-12.3V). TEST5/TEST6 (4.8V-5.2V). If there is any abnormality, check U27, D34, D36, D29, D32, T1, etc.

Standby auxiliary circuit and fan power: 12V output for miner's control board and large fan, VBUS2 voltage 410-430V, U28 chip 7 pin detection level start, measure VOUT voltage 12-12.45V. If abnormal, check U28 VCC power, MOS Q44, Q46 (and drive circuit) - output rectifier Q43, Q45; drive IC U30, etc. for damage, D37 U33 overvoltage protection, U34, U32 voltage stabilization feedback circuit, etc. 12V OUT J17 output for mining machine control board, J14 J15 J16 internal fan, note that if the fan is short-circuited, it will also cause 12V output abnormality.

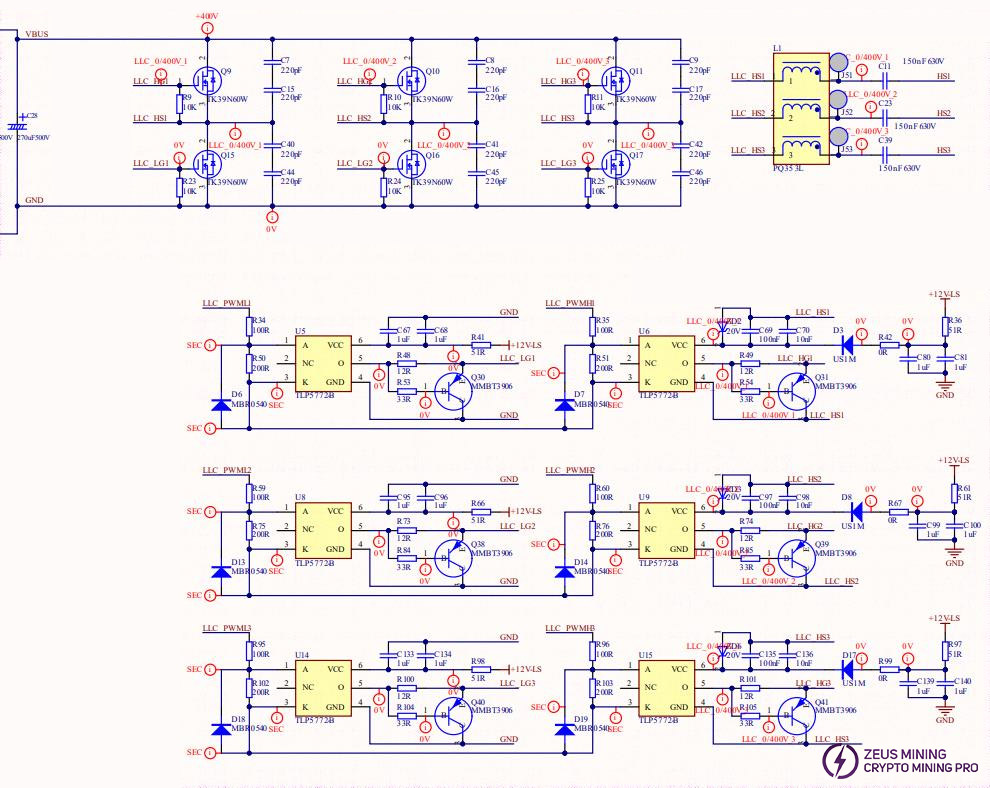

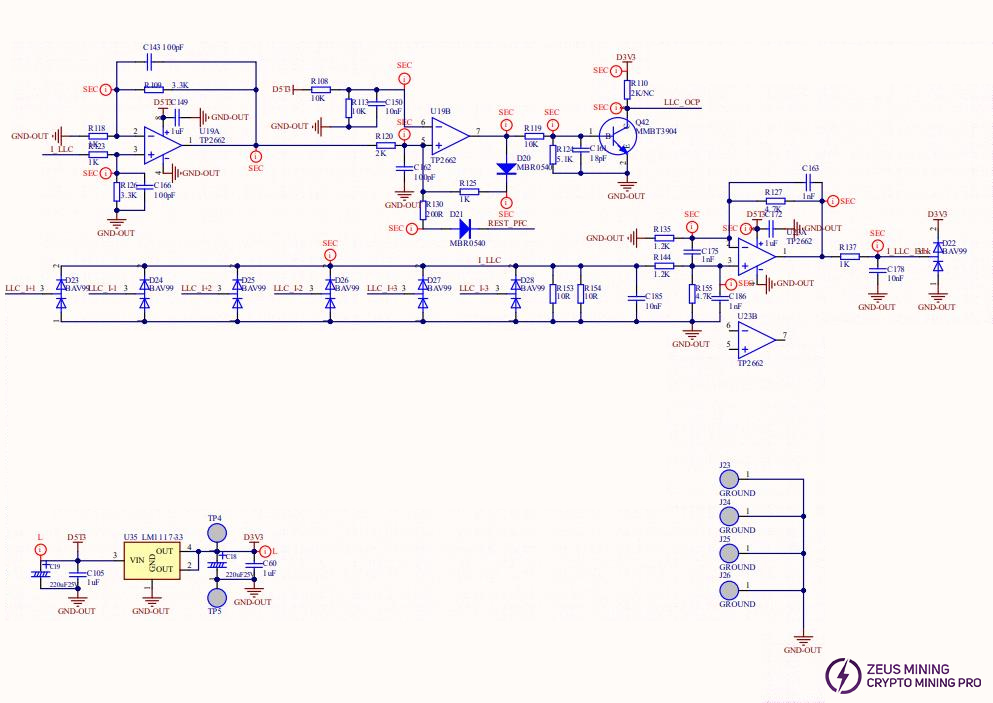

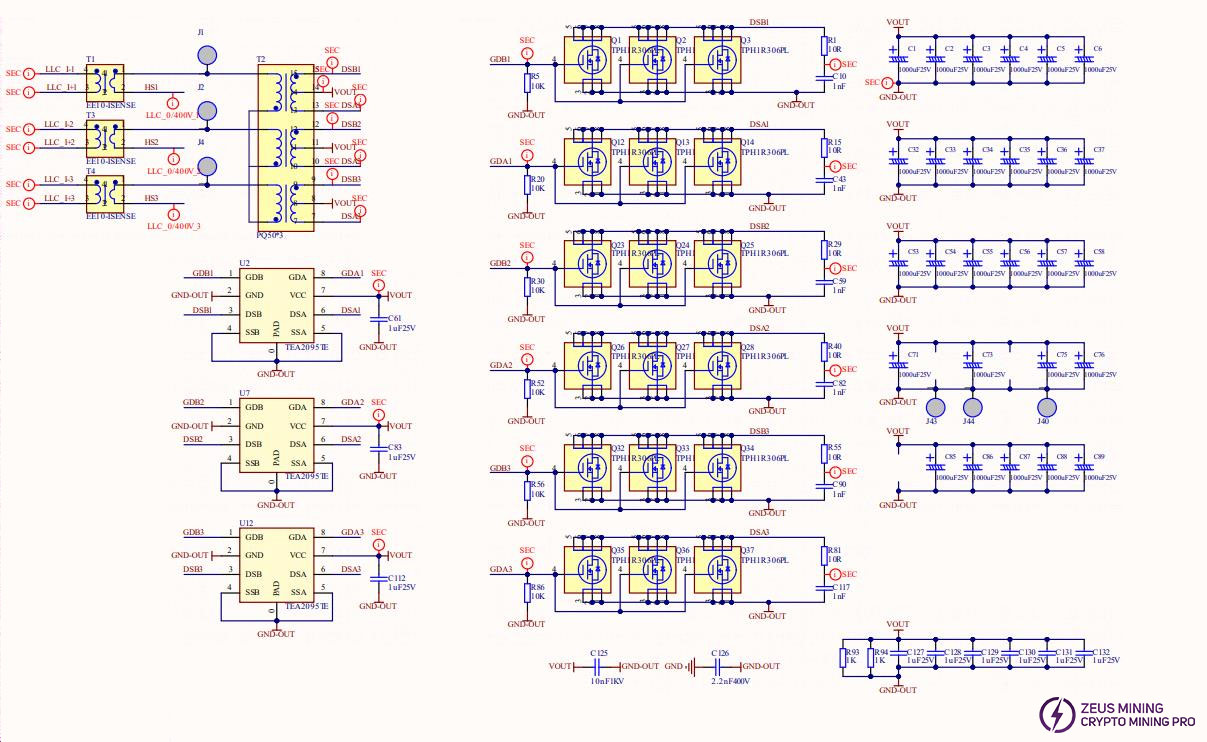

2.23 LLC circuit three-phase interleaved half-bridge main switch MOS and transformer conversion step-down synchronous rectification DC filter output circuit, focus on measuring LLC main switch MOS Q9, Q10, Q11, Q15, Q16, Q17 (if MOS is damaged, the corresponding drive resistor, triode and optocoupler need to be replaced), and whether the positive and negative poles of the output rectifier end SMD MOS are short-circuited, overcurrent protection circuit T1, T3, T4 mutual inductance, output synchronous drive U2, U7, U12 chips, etc.

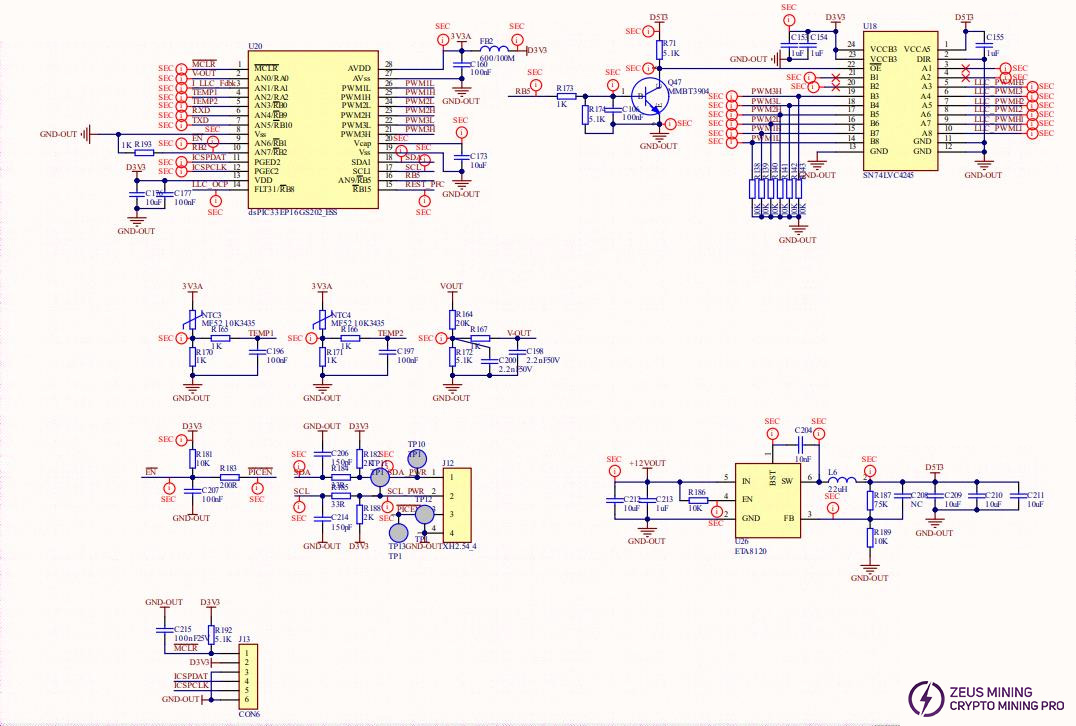

Voltage regulation port PIC driver control, U20 PIC chip, J13 flashing port, U18 driver IC.

LLC current detection and overcurrent protection

2.24 Main output MOS synchronous drive rectifier filter. If there is no DC output, measure whether the positive and negative copper strips are short-circuited, focus on confirming whether the low-voltage MOS is damaged, measure the MOS D-S pole and G-S pole respectively, if there is a short circuit, replace the corresponding MOS, U2, U7, U12 drive IC, solid-state capacitors are abnormal, etc.

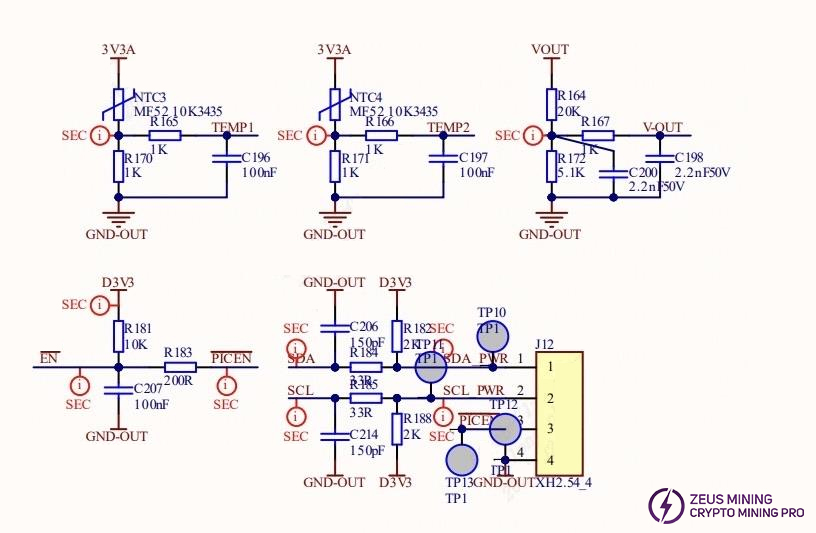

2.25 PIC controls the voltage regulation circuit, J12 is the voltage regulation communication port, short-circuit pins 3-4 and the default output is 15V after power-on. Under normal circumstances, pins 1, 3 and 4 are measured to be around 3.3V, otherwise the communication voltage regulation is abnormal.

2.26 SMD patch A side and plug-in B side device position silk screen diagram

2.3 Repair steps

2.31. Check whether the PSU has serious damage or deformation, and whether the DC fan and AC socket are damaged.

2.32. Power on AC220V, observe whether the fan rotates normally, and use a multimeter to measure whether the output J17 terminal voltage is 12V (12.1V-12.50) to eliminate false detection.

2.33. Open the case, check whether the components and solder surface are ignited or scorched, whether the auxiliary 12V circuit (Q14, Q46, etc.) is damaged, use a multimeter to check whether the AC input terminal F1 fuse is open, whether the PFC fast tube MOS Q5, Q18, Q4, Q19, slow tube Q6, Q7, Q8, Q20, Q21, Q22 are short-circuited or damaged, measure the LLC circuit main switch MOS Q9, Q10, Q11, Q15, Q16, Q17 and the output terminal SMD MOS Q1, Q2, Q3, Q12, Q13, Q14, Q23, Q24, Q25, Q26, Q27, Q28, Q32, Q33, Q34, Q35, Q36, Q37 to see if there is a short circuit. If there is a short circuit, the component position needs to be checked and replaced, and pay attention to the defective position. The driver IC circuit resistors, triodes, and isolation photocouplers around the MOS tube may be damaged and need to be inspected and replaced.

2.34. Check whether the small power auxiliary 12V VCC circuit U27, T5, D29, D32, D36, D34, large auxiliary circuit U28, Q44, Q46, output MOS Q43, Q45 and other components are short-circuited or open-circuited, and whether the surrounding components are burned, etc. If so, they need to be replaced.

2.35. If there is no abnormality in the above positions, the F1 fuse circuit is normal, and the DC fan rotates after AC power is turned on (if not, measure whether the fan socket has 12V, if normal, replace the fan), the output terminal J17 has 12V voltage, and measure whether the two ends of the two circuit PFC large capacitors C24, C25, C26, C27, C28 have DC400V-430V, otherwise check the PFC chip U13, drive U10, U11 VCC power has 12V, 5V, etc. judge whether the material is damaged and replace it, if there is no abnormality, the PWM circuit driver IC U3, U4 optical coupler circuit needs to be detected.

2.36. The output ripple is poor. Check whether the output solid-state capacitor and LLC high-frequency resonant capacitor are reversed or abnormal.

2.37. Other defects need to be further analyzed and judged according to the maintenance personnel's skills.

After the above inspections are completed, a single power supply is used to test the main DC output. J12 PIN 3-4 pins need to be short-circuited to output about DC15V, as shown in the figure EN-GND pin. Attention: short-circuiting errors may damage the chip. After the defective device is replaced and thesoldering is checked, the AC220V test can be performed. Note: If the circuit inspection is normal, the large capacitor has 410-430V after the signal is turned on, and other inspections are completed without abnormalities (such as no output after short-circuiting), it can also be judged that the PIC chip U20 firmware is re-burned or the IC is replaced and re-burned (generally, fewer defects are generated here).

2.4 If after-sales maintenance is possible, the control board fixture can be used to connect the APW17 PSU to power PIC port for testing, and the firmware can be tested with a TF card. According to the fixture test, the DC voltage is adjusted to 12V-15V, SDP, SCL, EN, and GND are PIC communication ports, and ATX-2X3 is 12V powering. Note that the lower is positive and the upper is negative. Attention: After the defective power supply is repaired, we only need to short-circuit the EN-GND pin of the PIC communication J12 port when powered on, and there will be voltage output, about 15V is normal. And we don’t need to test it separately (when the PIC microcontroller is broken, or the firmware is abnormal, after re-burning, we need use the small board to test and verify whether the voltage regulation is normal), or we can directly install the corresponding miner for testing.

After the power supply is repaired, 12V with a load of 18A, the main voltage DC15V needs to be tested with a load of 267A to be qualified.

2.5 Simple diagnosis and repair of common faults for mine power supply

No. | Fault phenomenon | Cause | Solution |

1 | Fan does not run, no 12V output | The power on the AC side of the power supply is abnormal. | 1. Check whether the AC input circuit of the PSU is normal and the plugs at both ends are not loose. 2. Check whether the power grid is connected and the voltage is normal. |

2 | Fan runs normally, no 12V output. | 1. Low grid voltage 2. Power supply protection | 1. Use a multimeter to confirm that the current voltage is above 205V to ensure that the PSU is turned on. 2. Check whether the PSU has output short circuit or overload. This will cause the PSU to enter a locked protection state. It will need to be repaired and then powered on again to recover. |

3 | After the PSU stops outputting for a few seconds, it resumes normal operation, continues to work for a few minutes, then stops outputting again, and repeats this process. | The power supply has entered over-temperature protection. | 1. Check whether the fan is running normally; 2. Check whether the heat dissipation duct of the PSU is blocked; 3. Check whether the PSU has been used for a long time and there is too much dust accumulated inside; 4. Check whether the power used by the PSU or the ambient temperature exceeds the value of the PSU's power limit curve. |

4 | Output is normal, but the fan is not running | Fan is broken | 1. Check if the fan is blocked by debris; 2. Fan is broken |

5 | The normally working PSU suddenly stops outputting and will not start again | Power supply overcurrent protection | Check whether the current of the load exceeds the upper limit of the PSU overcurrent protection for a moment. The PSU sets the overcurrent protection to a locked state to prevent the PSU from continuing to output when the load is abnormal, causing dangerous situations such as fire. |

2.6 After the PSU is repaired and tested normally, the main 15V circuit must be aged and run for 2 hours with a rated load of more than 90% (250A-267A) before it can be used by the customer end.