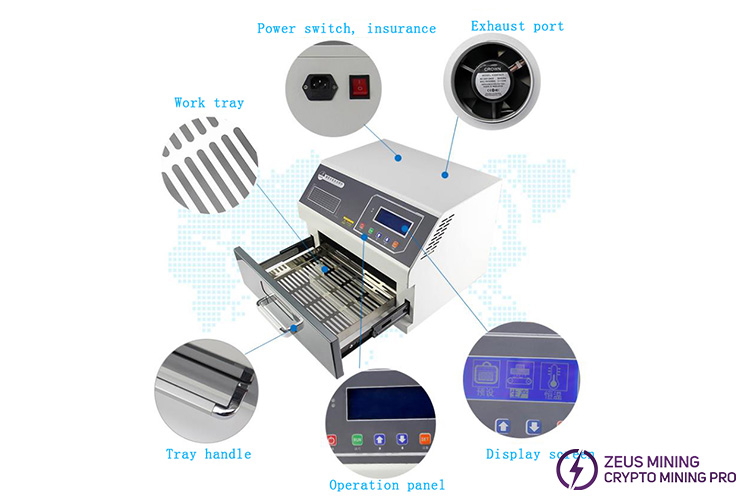

ZB5040HL reflow furnace is mainly a desktop reflow equipment for the production and maintenance of SMT and other products. The product uses high-efficiency far-infrared heating elements and distributed thermocouple temperature measurement devices. Through the microcomputer's precise control, the reflow furnace's temperature curve control is more precise, and the temperature of the reflow plane is more uniform. It can fully adapt to the reflow requirements of various alloys and lead-free solders. Its temperature curve is precise and adjustable, and the equipment has automatic fault detection and reporting functions. It includes multiple uses such as reflow, repair, and drying. The circuit structure adopts an efficient, convenient, and integrated design. It uses aluminum silicate high-temperature resistant and environmentally friendly thermal insulation cotton, which has an excellent thermal insulation effect and has been improved and upgraded in terms of performance, structure, and operation.

Attention: Please select the power cord plug when purchasing this product. We will give you an International universal socket adapter for free according to your choice.

Product parameters:

Model: ZB5040HL

Working power supply: AC220V 50~60Hz

Rated power: 3600W

Heating method: Infrared radiation heating and hot air circulation

Effective welding area: 500mm*400mm

Drawer size: 550*430*30mm

Net weight: 37.1kg

Gross weight: 40.1kg

Machine size: 675*600*312mm

Product features:

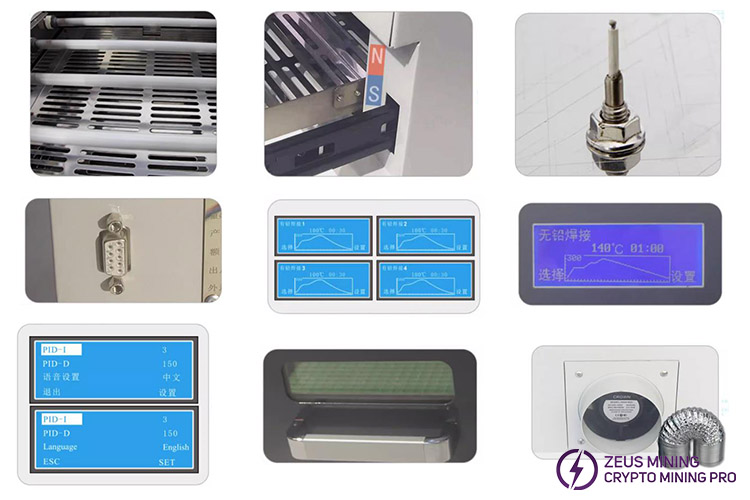

1) The interface of the liquid crystal display is clear (temperature, time, and curve are displayed at the same time);

2) Infrared heating tube, imported nickel-chromium heating wire, uniform heating, rapid heating, quality assurance;

3) Ceramic thermocouple, high sensitivity, accurate temperature measurement, strong stability;

4) Double-layer heat-insulating glass observation window to monitor the working conditions in the furnace in real-time.

The role and function of the temperature curve:

The drawer-type reflow oven is set with five temperature sections to simulate the five temperature zones of the tunnel-type reflow oven. The highest temperature points and corresponding holding times of each temperature section are designed to ensure the welding requirements of different PCB boards. The purpose and function of each temperature section are described as follows:

1. The purpose and function of the preheating section

The purpose is to heat the PCB board at room temperature, which can fully volatilize the moisture of the PCB board and eliminate the stress and some residual gas inside the PCB board.

2. The purpose and function of the heating section

The PCB board treated by the preheating section activates the flux in the tin paste during the heating section. It removes the oxides in the tin paste and on the surface of the components under the action of the flux to prepare for the welding process.

3. The purpose and function of the welding section

The main purpose of the welding section is to complete the SMT welding process. This stage is the highest temperature section in the entire reflow process; damaging components that do not meet the temperature requirements is easy. The temperature setting of this stage is generally about 30-50℃ higher than the melting point of the tin paste, and the time is generally set at about 2-5s.

4. Purpose and function of the insulation section

The function of the insulation section is to solidify the high-temperature liquid solder into a solid welding point. The solidification quality directly affects the solder's crystal structure and mechanical properties. Too fast a solidification time will cause the solder to form rough crystals and the solder joints to be uneven.

5. Purpose and function of the cooling section

Usually, it is enough to cool to a temperature that is not hot, but to speed up the operation process, it can also be directly pulled out of the drawer when it drops below 120℃ to cool down and end the process quickly.

Installation precautions:

1. The equipment should be installed where short-distance exhaust is convenient. The power supply should be equipped with a 15A high-current three-pin socket, and the grounding terminal must be reliably grounded.

2. The exhaust pipe should be made of aluminum with a diameter of 100mm. The outlet height of the exhaust pipe should be more than 1 meter higher than the machine's installation height, which is conducive to using the chimney exhaust effect of hot air.

3. The total length of the exhaust pipe shall not exceed 1.5 meters, the exhaust pipe shall not be bent more than 90 degrees, and the exhaust pipe bending radius shall be as large as possible. No exhaust fan shall be installed at the end of the exhaust pipe.

4. The mica pad in the equipment drawer cannot be removed.

5. Do not place other items on the top of the equipment, especially flammable liquids, such as "washing water, alcohol, methanol, gasoline," etc.

6. At the beginning of use, the equipment will discharge some odorous gas. This is a normal phenomenon. This odor will disappear after a period of use.

7. The power switch behind the machine should be turned off when the equipment is not in use. When the software is turned off, the machine's main control board is still working. If the machine is not used for a long time, it should be disassembled and put back into its original packaging for storage.

For a more detailed introduction of ZB5040HL reflow oven, please see the article: ZB5040HL lead free reflow oven operation tutorial.

Related Products:

Payment method:

How to determine product prices and shipping costs?When you are ready to buy one or more products. You can consult the sales Manager to get a sample of the proforma invoice. The category, product price, and freight are included. |

||

How to complete the payment?We have the following payment methods. You can tell our sales Manager which payment you prefer and complete it. After the customer service checks and confirms the payment is completed. Provide the proforma invoice. And we will prepare to ship. |

||

Cryptocurrency Payment |

||

|

Bitcoin - The payment method at the designated address is efficient and practical and can be used anywhere in the world. Wallet Address |

|

|

USDT - The payment method at the designated address is efficient and practical and can be used anywhere in the world. Wallet Address |

|

|

ETH - The payment method at the designated address is efficient and practical and can be used anywhere in the world. Wallet Address |

|

|

LTC - The payment method at the designated address is efficient and practical and can be used anywhere in the world. Wallet Address |

|

|

USDC - The payment method at the designated address is efficient and practical and can be used anywhere in the world. Wallet Address |

|

Bank Transfer |

||

|

Wire transfer - USD - SeaTree Card Number |

|

|

Wire transfer - USD, EUR, GBP, HKD, CNH, CAD, SGD, JPY, AUD, NZD Card Number |

|

|

JP MORGAN CHASE BANK, N.A. Card Number |

|

|

Wire transfer - USD - Zhou sicong Card Number |

|

|

人民币支付 - CNY payment Card Number |

|

Other payment methods |

||

|

||

|

Cooperation express: |

|

Q: When will we ship after payment?

A: In order to ensure that the products we ship are in good condition. Issued approximately 1-2 days after receiving your payment.

Q: What if the product is damaged during transportation?

A: We will use a more robust package when shipping to avoid damage to the goods, and we can purchase transportation insurance in advance to reduce the loss of in the transport. although this problem is not common.

Q: What payment methods do we support?

A: We support bank transfer, wire transfer, BTC, third-party guarantee and Paypal.

Q: What should I do if there is a problem after receiving the products?

A: We have established good relationships with maintenance departments in many countries/regions in the world. For example, Venezuela, Iran, etc. If you have any questions within 3 days after receiving the goods, you can apply for after-sales service on the "My Order" page.

Q: Which express we support?

A: We will choose the cheapest and fastest transportation method for you. And we support DHL, UPS, TNT, Fedex, BRE, and also have express delivery services, such as Russia, the United States, Kuwait, etc.