Overview

The Antminer S19 Pro+ Hydro is one of Bitmain's 19 hydro miner series versions. Power supply APW11 is part of the S19 Pro+ Hydro miner. All S19 Pro+ Hydro miners are tested and configured before shipping to ensure easy setup.

I. Pre-use inspection

1. New machine receipt inspection: When signing for a new machine, please check the appearance of the package. After unpacking, please check the miner housing, fan, connection cables, and cables. Check whether the miner has any abnormal noise.

2. Precautions for use

a. Please connect the miner to a router or switch without POE function;

b. The miner can only be connected to a router or switch via wired mode;

c. The recommended ambient temperature is 25~30℃;

d. The recommended ambient humidity is lower than 65%RH;

e. Pay attention to dust and foreign matter prevention to avoid corrosion of the hash board or affecting the heat dissipation of the miner;

f. It is recommended to use Google Chrome or Firefox to browse the server background.

II. Basic instructions

a. Please refer to the layout above to place your goods in usage in case of any damage.

b. DO NOT remove any screws and cables tied to the product.

c. Please note that the actual miner shall prevail.

d. There must be an external specific Surge Protection device complying with IEC/EN 61643-11 either in front of the power supply or outside the end system (in a separate distribution box or as part of the building installation).

e. Do not plug or remove the device when it is powered on.

f. The external power supply shall have a disconnecting device, which can disconnect L1&L2&L3 simultaneously.

g. The S19 Pro+ Hydro miner shall be used simultaneously with the ANTSPACE HK3.

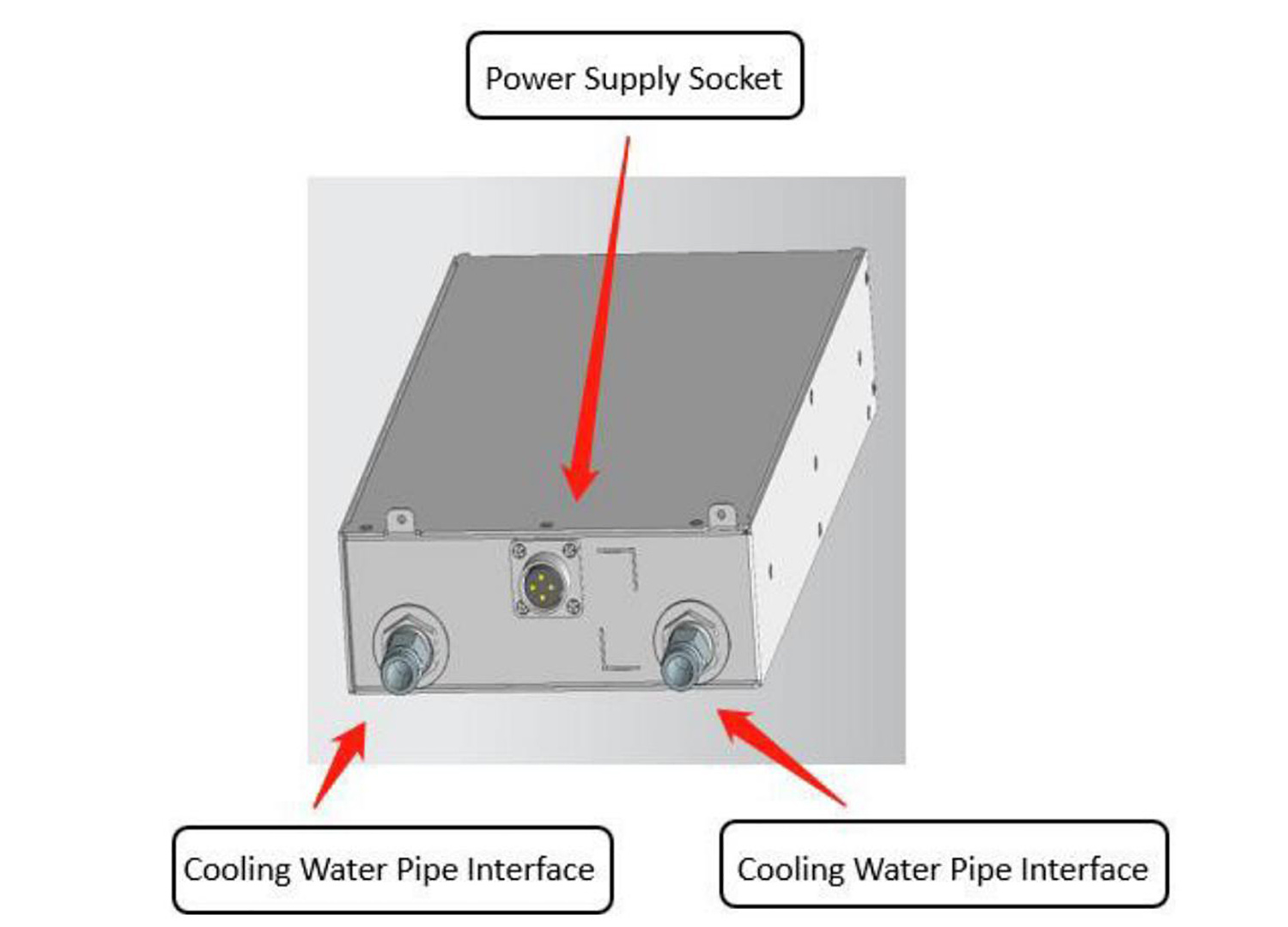

1. S19 Pro+ Hydro miner components

The main components of the S19 Pro+ Hydro miner are shown in the figure below:

APW11 Power Supply:

Note:

Note:

Power supply APW11 is part of the S19 Pro+ Hydro miner. For detailed parameters, please refer to the specifications below.

2. Miner specifications

Product Glance | Value | ||||

Version | S19Pro+ Hydro | ||||

Model | j0-10 | ||||

Crypto Algorithm/Coins | SHA256/BTC/BCH | ||||

Hashrate,TH/s | 198 ± 3% | 191 ± 3% | 184 ± 3% | 177 ± 3% | 170 ± 3% |

Power on wall@Tj65°C, Watt(1-1) | 5445 ± 5% | 5253 ± 5% | 5060 ± 5% | 4868 ± 5% | 4675 ± 5% |

Power efficiency on wall @Tj65°C, J/TH(1-1) | 27.5 ± 5% | 27.5 ± 5% | 27.5 ± 5% | 27.5 ± 5% | 27.5 ± 5% |

Detailed Characteristics | Value |

Power Supply | |

Power supply AC input voltage, Volt (2-1) | 342~418 |

Power supply AC Input Frequency Range, Hz | 47~63 |

Power supply AC Input current, Amp(2-2) | 30 |

Hardware Configuration | |

Network connection mode | RJ45 Ethernet 10/100M |

Server Size (Length*Width*Height, w/o package), mm | 410*196*209 |

Server Size (Length*Width*Height, with package), mm | 570*316*430 |

Net weight, kg | 15.2 |

Gross weight, kg | 17.5 |

Environment Requirements | |

Operation temperature, °C (2-3) | 0~40 |

Inlet water temperature, °C | 20-40 |

Water flow L/min | 8±10% |

Water pressure bar | ≤3.5 |

Storage temperature, °C | -20~70 |

Operation humidity(non-condensing), RH | 10~90% |

Notes:

1) Inlet water temperature;

2) Caution: Wrong input voltage may probably cause miner damage;

3) Three-phase AC input, 10A per wire;

4) Operation altitude is recommended below 2000m.

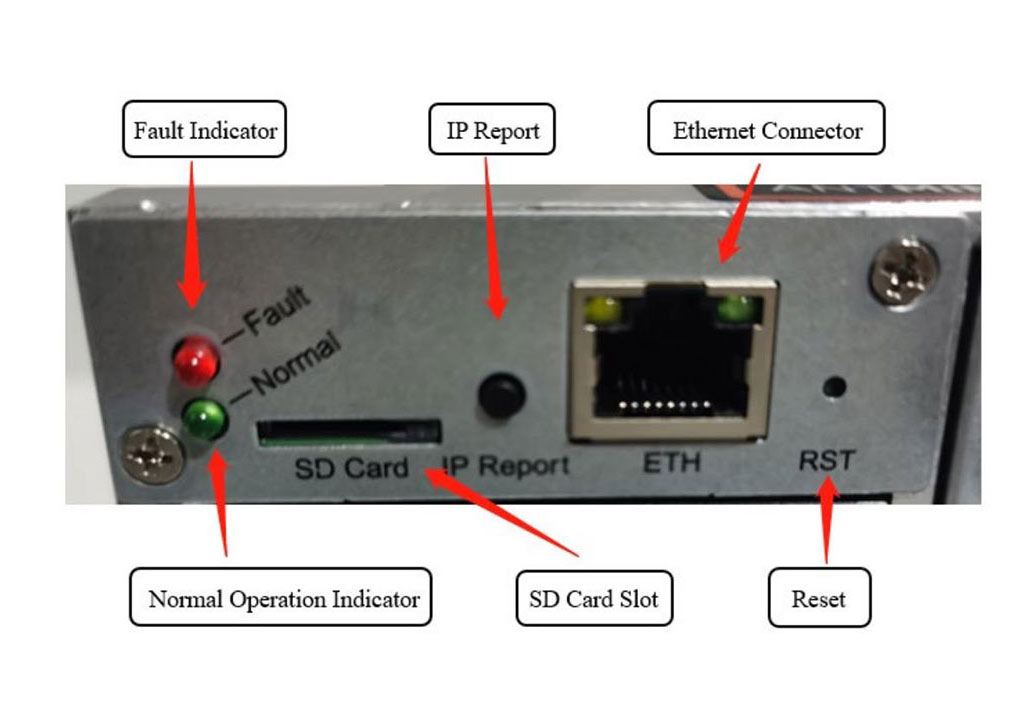

3.control board location interface description

SD card: SD card socket.

IP Report: Use IP Report software to report the IP of this miner to the computer.

ETH: Network cable interface.

Reset: Server factory reset button.

Fault: Fault alarm light. In most cases, flashing indicates a fault.

Normal: Running indicator light. In most cases, flashing indicates that the machine is working normally.

III. Setting up the Miner

1. Wiring and inspection

Network cable connection: The ETH marked on the interface panel of the mining machine is the network cable interface. Pay attention to the direction when plugging in the cable. Please insert the crystal head in place. After it is inserted in place, we will generally hear a light "click".

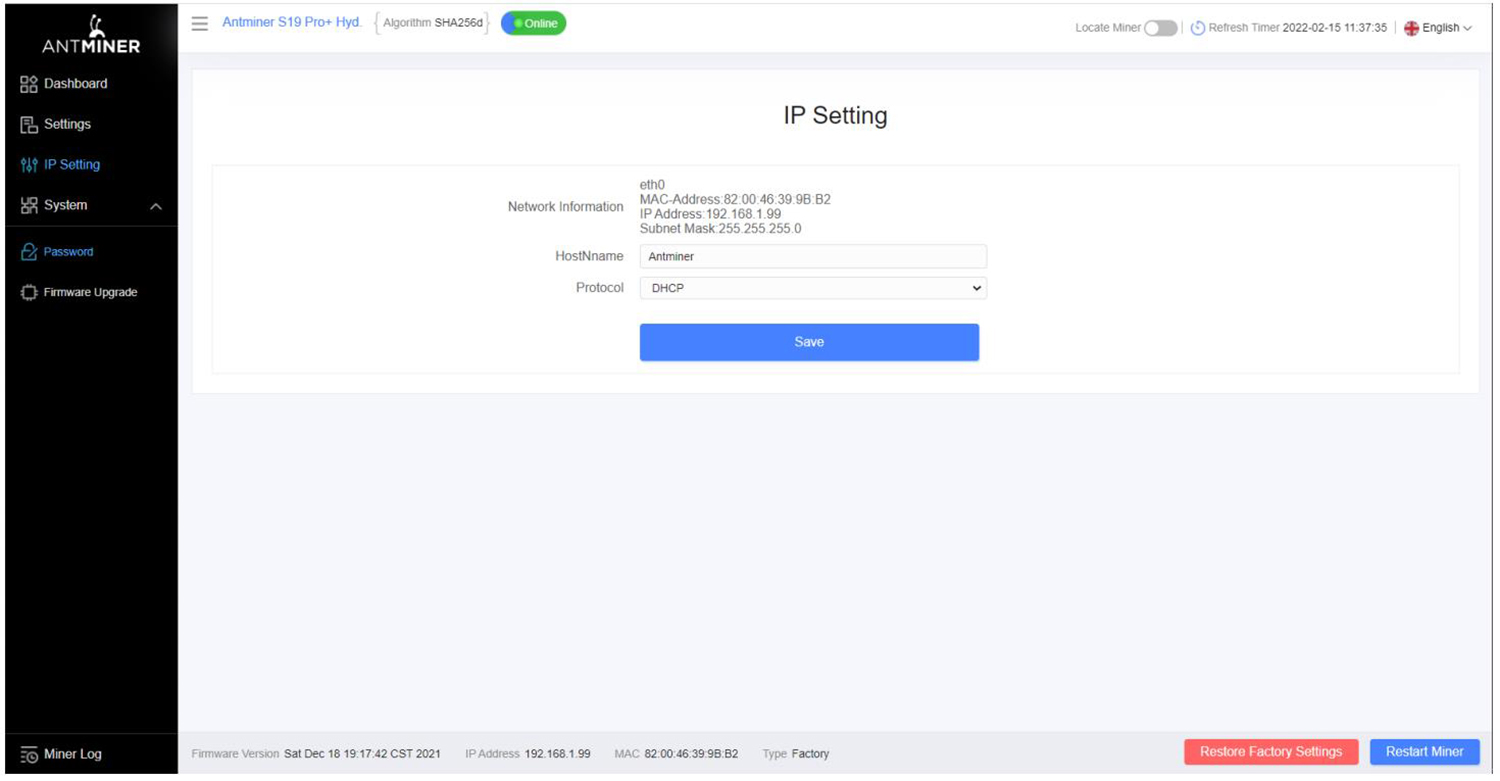

2. Enter the miner

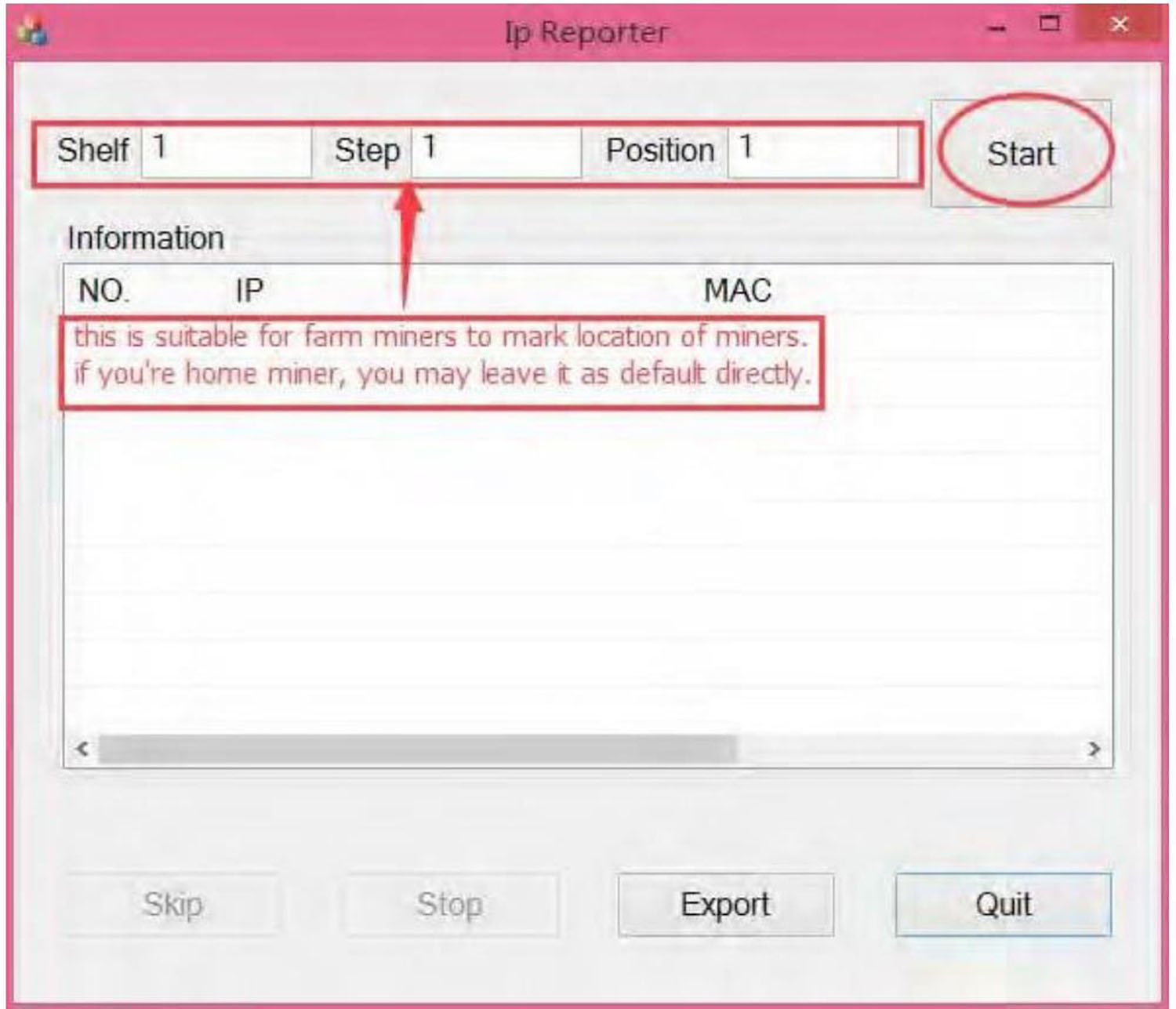

Find IP: After the power supply is supplied, the miner starts to start. After the green light starts flashing, we can find the IP. We can use the IP Report software to find the IP. The file IP Reporter.zip is supported by Microsoft Windows only.

3. Download the following file: IP Reporter.zip. Read the article How to use IP Reporter? to learn more.

4. Extract the file.

The default DHCP network protocol distributes IP addresses automatically.

5. Right-click IP Reporter.exe and run it as Administrator.

6. Select one of the following options:

a. Shelf, Step, Position – suitable for farm miners to mark the location of the miners.

b. Default – suitable for home miners.

7. Click Start

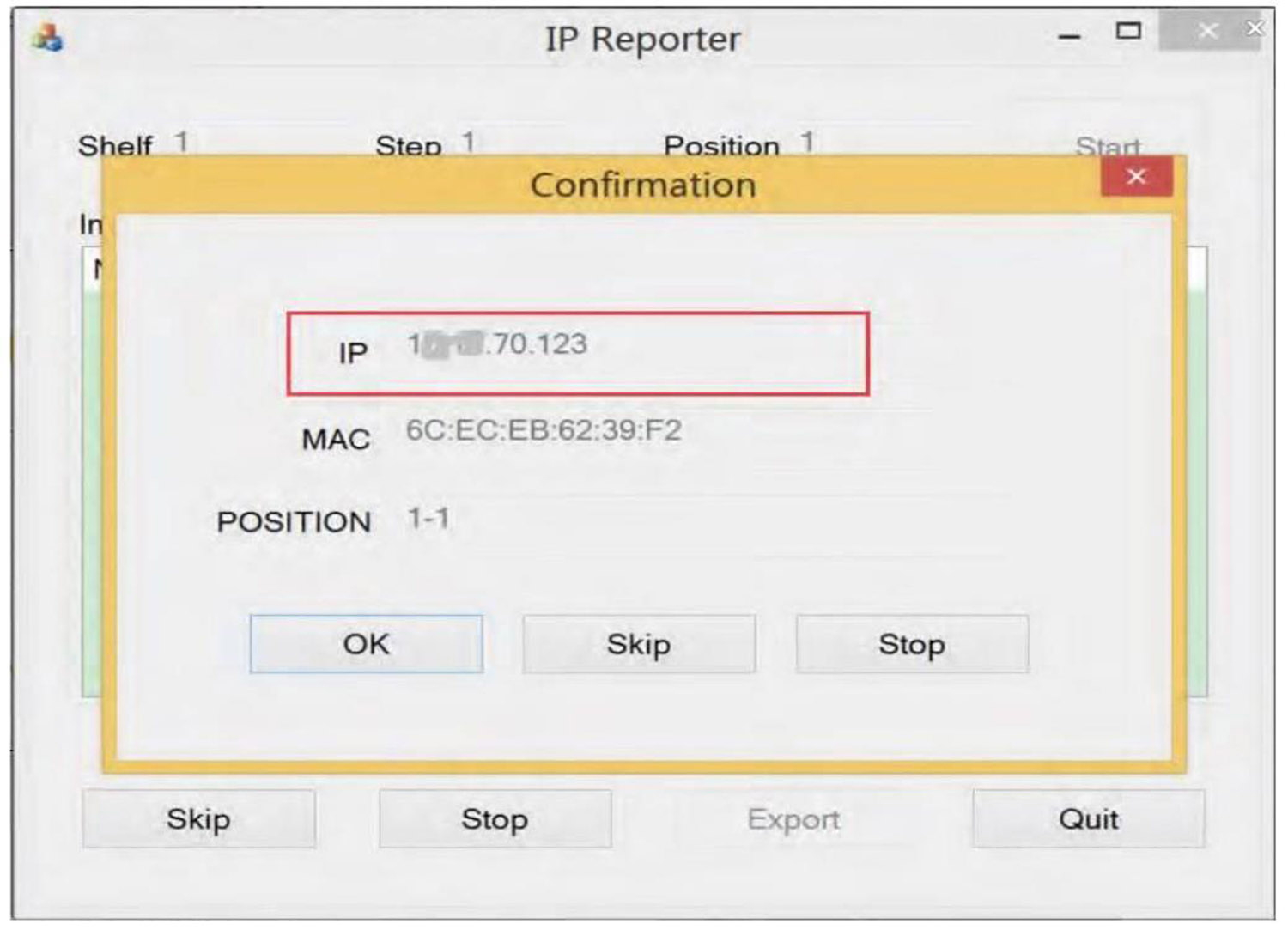

8. On the control board, click the IP Report button. Hold it down until it beeps (about 5 seconds). The IP address will be displayed in a window on your computer screen.

9. In your web browser, enter the IP address provided.

10. Proceed to log in using root for both the username and password.

11. In the Protocol section, you can assign a Static IP address (optional).

12. Enter the IP address, Subnet mask, gateway, and DNS Server.

13. Click “Save.”

14. Click Gateway and DNS Server to learn more about them.

IV. Configuring the Miner

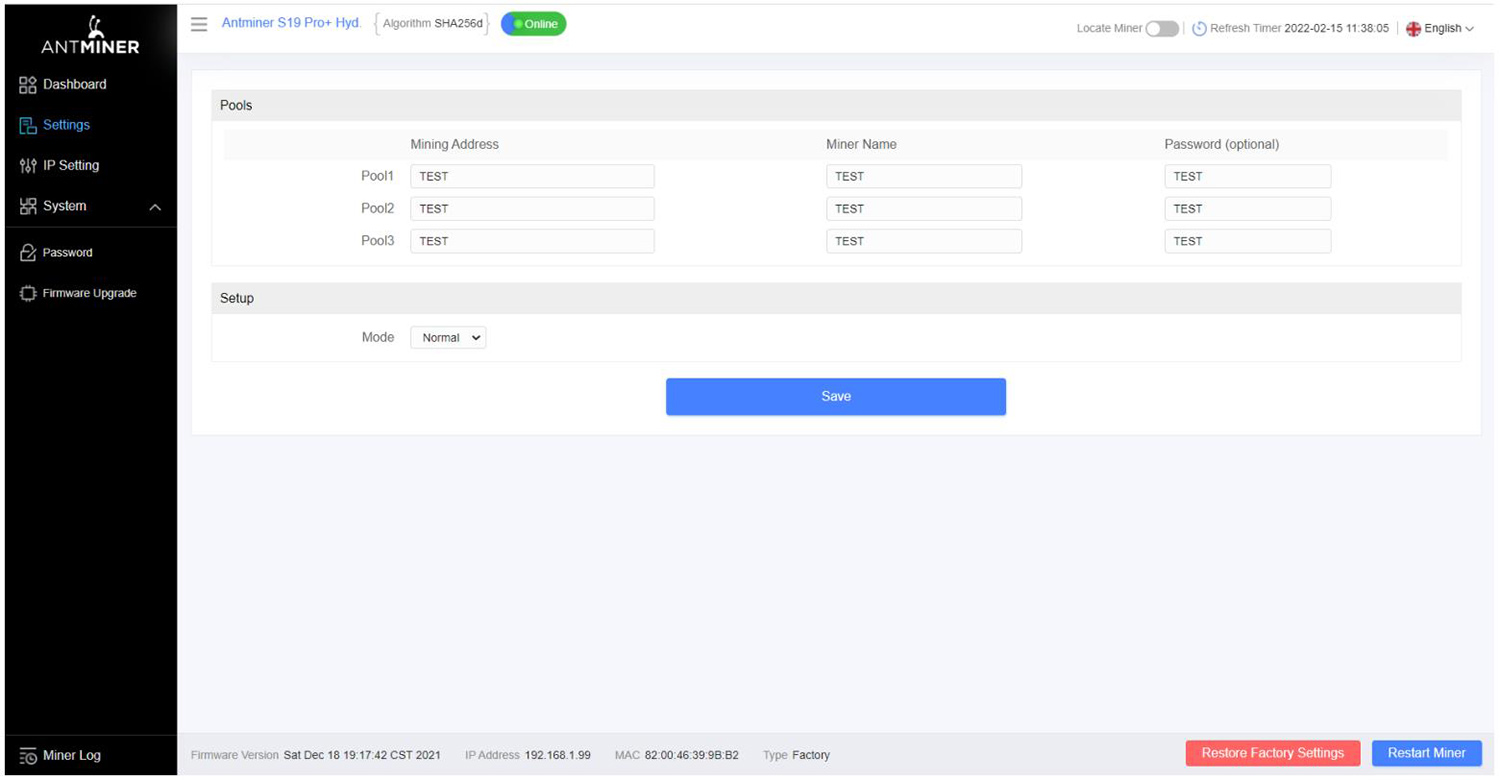

Setting up the Pool

1. Click Setting as below.

2. Set the options according to the following table.

Option | Description |

Mining address | Enter the address of your desired pool. The S19 Pro+ Hydro miners can be set up with three mining pools, with decreasing priority from the first pool (pool 1) to the third pool (pool 3). The pools with low priority will only be used if all higher priority pools are offline. |

Name | Your worker ID on the selected pool. |

Password | The password for your selected worker. |

3. Click Save after the configuration.

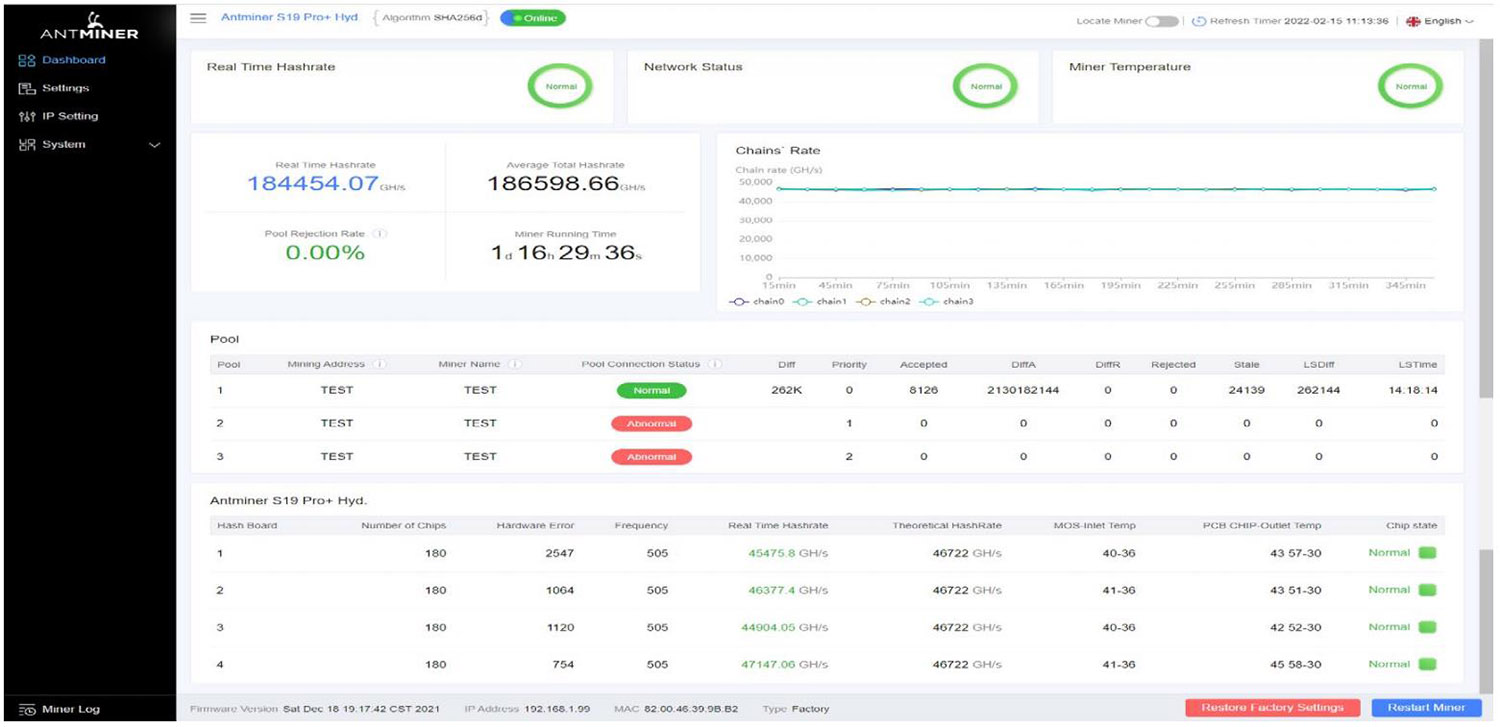

V. Monitoring Your Miner

To check the operating status of your miner (taking S19 Pro+ Hydro 184T as an example):

1. Click dashboard marked below to check the miner status.

Note: The frequency of the S19 Pro+ Hydro miner is fixed with the value 505 MHz. The firmware will stop running when the Temp (PCB) reaches 75℃, or the water temperature is either greater than 45℃ or lower than 20℃; there will be an error message “Fatal Error: Temperature is too high!” shown on the Bottom of the Kernel log page.

2. Monitor your miner according to the descriptions in the following table:

Option | Description |

Number of chips | Number of chips detected in the chain. |

Frequency | ASIC frequency setting. |

Real Hash rate | Real-time hash rate of each hash board (GH/s). |

Inlet Temp | Temperature of the inlet (°C). |

Outlet Temp | Temperature of the outlet (°C). |

ASIC status | One of the following statuses will appear: The Green Icon - indicates normal The Red Icon - indicates abnormal |

VI. Administering Your Miner

1. Checking your firmware version

Check steps:

1) Enter the backstage of your miner, and find the firmware version on the bottom.

2) File System Version displays the date of your miner's firmware. In the example below, the miner is using firmware version 20211218.

2. Upgrading your system

Make sure that the S19 Pro+ Hydro miner remains powered during the upgrade process. If power fails before the upgrade is completed, you will need to return it for repair.

Upgrade steps:

1) In System, click Firmware Upgrade.

2) For keep settings:

a. Select “keep settings” to keep your current settings (default).

b. Unselect “keep settings” to reset the miner to default settings.

3) Click the browse button and navigate to the upgrade file. Select the upgrade file, then click Update.

4) When the upgrade is completed, restart the miner, and it will turn to the setting page.

5) Click one of the following options:

a. Reboot - to restart the miner with the new firmware.

b. Go Back - to continue mining with the current firmware. The miner will load the new firmware the next time it is restarted.

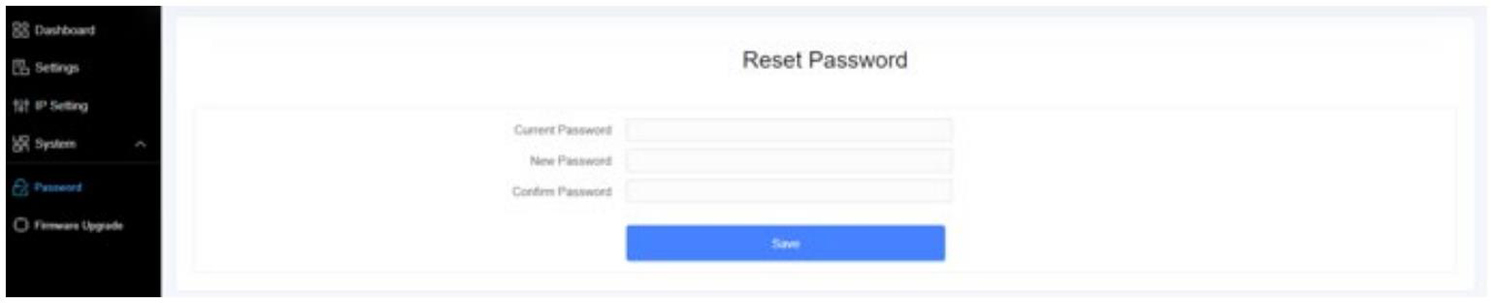

3. Modifying your password

1) In System, click the Password tab.

2) Set your new password, then click Save.

4. Restoring initial settings

1) Turn on the miner and let it run for 5 minutes.

2) Press and hold the Reset button for 10 seconds on the control board.

Resetting your miner will reboot it and restore its default settings. In addition, the red LED will flash once every 15 seconds if the reset is operated successfully.

VII. Environmental Requirements

Please run your miner by the following requirements:

1. Basic environmental requirements:

1) Climatic conditions:

Description | Requirement |

Operating Temperature | -20-50℃ |

Operating Humidity | 20-90%RH (non-condensing) |

Storage Temperature | -20-70℃ |

Storage Humidity | 5-95%RH(non-condensing) |

Altitude | <2000m |

2) Site requirements of the miner running room:

a. Please keep the miner running room away from industrial pollution sources:

b. The distance between heavy pollution sources such as smelters and coal mines should be more than 5km.

c. The distance should be more than 3.7km for moderate pollution sources such as chemical, rubber, and electroplating industries.

d. The distance should be more than 2km for light pollution sources such as food and leather processing factories. If unavoidable, the site should be chosen in the perennial upwind direction of the pollution source.

e. Please do not set your location within 3.7km from the seaside or the salt lake. If unavoidable, it should be built as airtight as possible, equipped with air conditioning for cooling.

3) Electromagnetic environmental conditions:

a. Please keep your site away from transformers, high-voltage cables, transmission lines, and high-current equipment; for example, there should be no high-power AC transformers (>10KA) within 20 meters and no high-voltage power lines within 50 meters.

b. Please keep your site away from high-power radio transmitters; for example, there should be no high-power radio transmitters (>1500W) within 100 meters.

2. Other environmental requirements:

The miner running room shall be free of explosive, magnetically conductive, and corrosive dust. The requirements of mechanical active substances are shown below:

1) Requirements of mechanical active substances

Mechanical Active Substance | Requirement |

Sand | <= 30mg/m3 |

Dust (suspended) | <= 0.2mg/m3 |

Dust (deposited) | <=1.5mg/m2h |

2) Requirements of corrosive gas

Corrosive Gas | Unit | Concentration |

H2S | ppb | < 3 |

SO2 | ppb | < 10 |

Cl2 | ppb | < 1 |

NO2 | ppb | < 50 |

HF | ppb | < 1 |

NH3 | ppb | < 500 |

O3 | ppb | < 2 |

Note: ppb (part per billion) refers to the unit of concentration; 1ppb stands for the volume ratio of part per billion.